GSSD06

Member

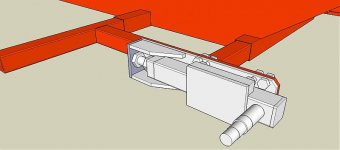

Great pictures of the truss plates, definitely worth a thousand words each.

I should probably correct any misconceptions about me so I am not put in the expert category, but I will rely on your ability to take any suggestions for their value alone.

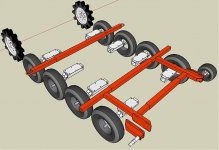

What I intended to do for alignment was to run a piano wire or string line in a loop aroung the drive sprockets and idlers to line up the bogies.

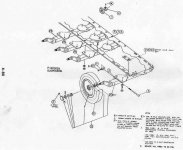

I would suggest you think carefully about how you weld the truss plates to the 2" square tubes on the Imp frame. Welds inline with the square tubes may have less negative impact on strength than perpindicular welds. Welds on the vertical faces of the tubes may have more impact on strength than welds on the top and bottom of the tubes, mostly because one would expect more vertical forces on the tubes than lateral forces.

If you look at a truck frame, you will typically not see any welds on the vertical members, the same is true for the I-beams of cranes, because the major forces are vertical and all the strength of the vertical member is desired. With a few horizontal gussets you could spread the weld over a longer area, and use skip welds to allow for more flexing.

Two major sources of concern for breakage are: catastrophic failure, for instance from shock; and long-term fatigue, say from repeated flexing.

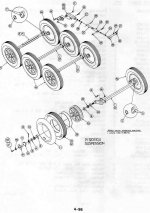

Intuitively, the same two wheels are attached to the square tube, so unless the torsion suspension is stiffer or you plan on operating more heavily loaded and/or hitting bumps harder, then you would not expect more force to be transmitted into the existing tube.

When it comes to long term fatigue, if there is too much weld concentrated in a small area next to a flexible member, then right at the edge of the weld where stiff meets flexible, it is common to have failure. This phenomenon is very common in welded hydraulic plumbing that is flexing, pin hole leaks develop in the welds from mechanical fatigue.

That is the reason why I had opted for a sub-frame, to spread the load out over a larger area. It also allows all the torsion half-axles to be mounted in a trailing arm configuration. In a leading arm configuration you may have to be concerned with the possibility that the geometry allows you to hit a bump with the force inline with the trailing arm, not rotating the torsion arm but transferring all or most of the energy into the frame.

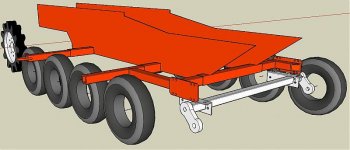

As far as clearance goes, it is hard to tell if what you have will clear. If I understand where your concern is about clearance, what some suspension systems incorporate is additional idlers to keep the top of the track from hitting anything, they might be more efficient than a skid plate.

Mtncrawler brought up a really good point about having the bogie wheels too much lower than stock, you could likely develop a lot more rocking chair motion from the shorter contact area with the snow, I can just envision those snowmobile moguls on a hard packed road, might need some Dramamine.

When it comes to 1/4" versus 3/8" thick, my instinct is that 3/8" would be very stiff and that you probably need to retain some flexibility. I would be most concerned about the part of the existing 2" square tube between the inside truss plate and the 18" wide tunnel of the Imp. That section is very short, will now be very stiff. That might mean that long-term fatigue is more of an issue than catastrophic failure.

I would think the 700# times eight torsion axles would be enough if your machine is around 3000#, but you might want to talk to Flexiride, they were very helpful before when I called them. Where they told me they have run into trouble is with double and triple axle trailers where the load that an individual axle encounters is much higher than one would imagine. I was told that typically the horizontal torsion axle snaps off. Here you have a quad axle vehicle, so in the wrong conditions you can get a lot of force on one bogie.

I should probably correct any misconceptions about me so I am not put in the expert category, but I will rely on your ability to take any suggestions for their value alone.

What I intended to do for alignment was to run a piano wire or string line in a loop aroung the drive sprockets and idlers to line up the bogies.

I would suggest you think carefully about how you weld the truss plates to the 2" square tubes on the Imp frame. Welds inline with the square tubes may have less negative impact on strength than perpindicular welds. Welds on the vertical faces of the tubes may have more impact on strength than welds on the top and bottom of the tubes, mostly because one would expect more vertical forces on the tubes than lateral forces.

If you look at a truck frame, you will typically not see any welds on the vertical members, the same is true for the I-beams of cranes, because the major forces are vertical and all the strength of the vertical member is desired. With a few horizontal gussets you could spread the weld over a longer area, and use skip welds to allow for more flexing.

Two major sources of concern for breakage are: catastrophic failure, for instance from shock; and long-term fatigue, say from repeated flexing.

Intuitively, the same two wheels are attached to the square tube, so unless the torsion suspension is stiffer or you plan on operating more heavily loaded and/or hitting bumps harder, then you would not expect more force to be transmitted into the existing tube.

When it comes to long term fatigue, if there is too much weld concentrated in a small area next to a flexible member, then right at the edge of the weld where stiff meets flexible, it is common to have failure. This phenomenon is very common in welded hydraulic plumbing that is flexing, pin hole leaks develop in the welds from mechanical fatigue.

That is the reason why I had opted for a sub-frame, to spread the load out over a larger area. It also allows all the torsion half-axles to be mounted in a trailing arm configuration. In a leading arm configuration you may have to be concerned with the possibility that the geometry allows you to hit a bump with the force inline with the trailing arm, not rotating the torsion arm but transferring all or most of the energy into the frame.

As far as clearance goes, it is hard to tell if what you have will clear. If I understand where your concern is about clearance, what some suspension systems incorporate is additional idlers to keep the top of the track from hitting anything, they might be more efficient than a skid plate.

Mtncrawler brought up a really good point about having the bogie wheels too much lower than stock, you could likely develop a lot more rocking chair motion from the shorter contact area with the snow, I can just envision those snowmobile moguls on a hard packed road, might need some Dramamine.

When it comes to 1/4" versus 3/8" thick, my instinct is that 3/8" would be very stiff and that you probably need to retain some flexibility. I would be most concerned about the part of the existing 2" square tube between the inside truss plate and the 18" wide tunnel of the Imp. That section is very short, will now be very stiff. That might mean that long-term fatigue is more of an issue than catastrophic failure.

I would think the 700# times eight torsion axles would be enough if your machine is around 3000#, but you might want to talk to Flexiride, they were very helpful before when I called them. Where they told me they have run into trouble is with double and triple axle trailers where the load that an individual axle encounters is much higher than one would imagine. I was told that typically the horizontal torsion axle snaps off. Here you have a quad axle vehicle, so in the wrong conditions you can get a lot of force on one bogie.