I suspect that on-the-job training policy existed for decades, and with little "adult supervision"...It's like the 1953 help wanted ad read, "No experience needed. Learn to weld and fabricate on actual customer vehicles."

-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1953 Tucker Sno Cat 443 Mt Washington WMTW Channel 8 Restoration

- Thread starter Track Addict

- Start date

Live WMTW weather report from atop MT Washington is that spring has sprung!

Amazing what a short drive can do in New England!

Ok experts calling you in to support.

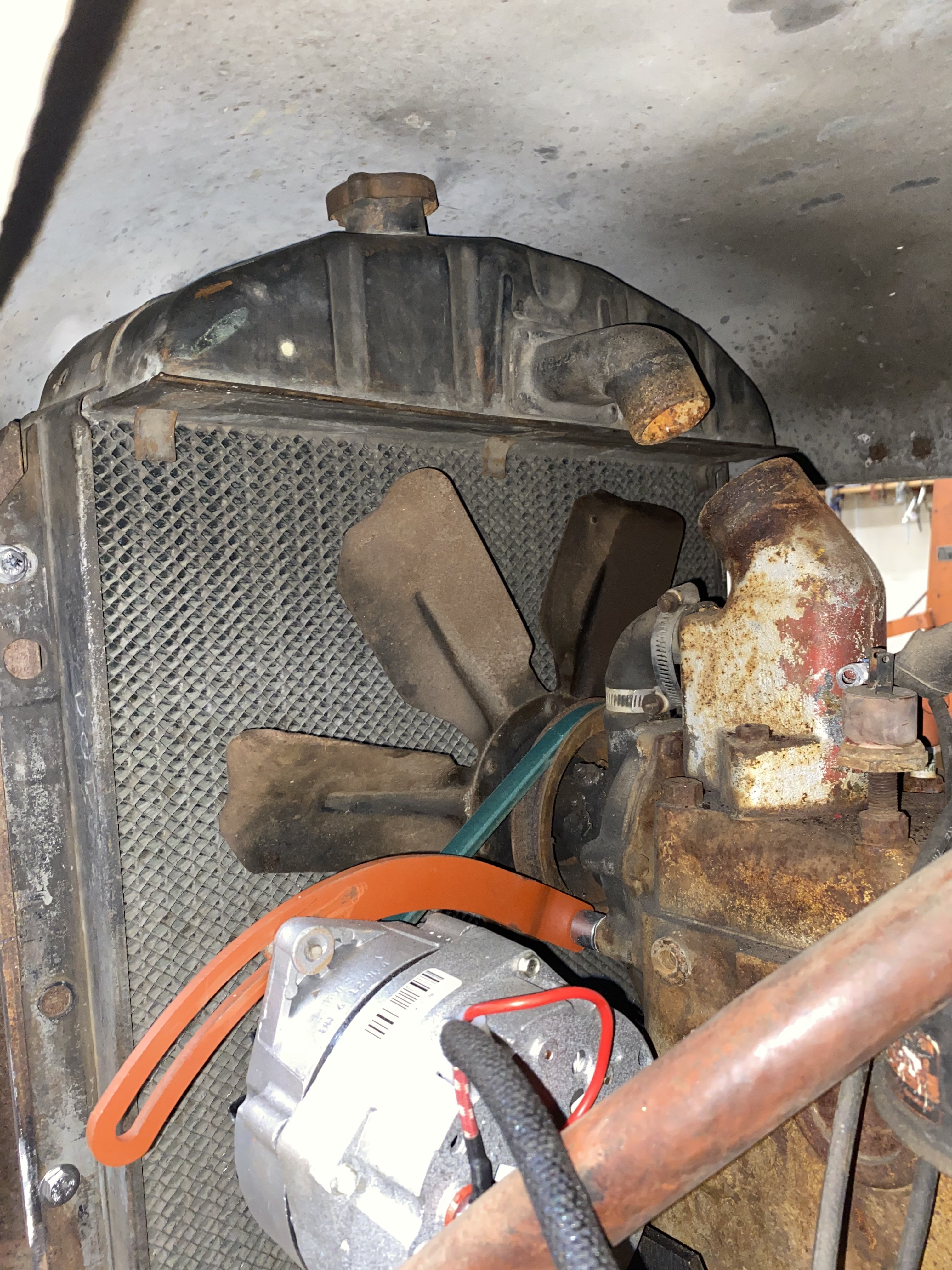

Radiator is in fan hits. There is no more height to go up. All the pics of 53 tuckers I found have this radiator mounted approx same height. The cap is touching the hood so that's that.

4 blade fan measures about 19 1/4". The six blade on another flathead I have is under 18 which clears.

Junkyard life could have swapped any of the oddities on this. Should have been a 4 blade fan.

Love some pics and mounting measurements from 53 vintage cats!

Radiator is in fan hits. There is no more height to go up. All the pics of 53 tuckers I found have this radiator mounted approx same height. The cap is touching the hood so that's that.

4 blade fan measures about 19 1/4". The six blade on another flathead I have is under 18 which clears.

Junkyard life could have swapped any of the oddities on this. Should have been a 4 blade fan.

Love some pics and mounting measurements from 53 vintage cats!

lol

tucker fitted everything, by beating it into place, to make a custom fit, no snow to deep, build no two the same

tucker fitted everything, by beating it into place, to make a custom fit, no snow to deep, build no two the same

Last edited:

Things definitely are not what they seem after almost 70 years of who did what.

Fan was wrong and the mounting holes in the radiator were too low from prior Dodge application.

About 1954 dodge switched to a six blade fan to improved the cooling situation on the non pressurized system of the 251 and eventually 265z This is a popular upgrade on cars prior to that error. So another sensible upgrade to solve the wrong fan and benefit the usability.

Finally got the body off. The windshield frame was through bolted and rusted. Easiest was to grind the screw head flat carefull not to hit the aluminum, center punch, then 1/8" drill and out them came.

Next is to hook the hoses back up full with antifeeeze and start it back up. From there will remove the skins from the door frame reinstall and adjust. Passenger side hinge broke and bent in life with a poor repair.

Fan was wrong and the mounting holes in the radiator were too low from prior Dodge application.

About 1954 dodge switched to a six blade fan to improved the cooling situation on the non pressurized system of the 251 and eventually 265z This is a popular upgrade on cars prior to that error. So another sensible upgrade to solve the wrong fan and benefit the usability.

Finally got the body off. The windshield frame was through bolted and rusted. Easiest was to grind the screw head flat carefull not to hit the aluminum, center punch, then 1/8" drill and out them came.

Next is to hook the hoses back up full with antifeeeze and start it back up. From there will remove the skins from the door frame reinstall and adjust. Passenger side hinge broke and bent in life with a poor repair.

Hoses mounted for now and radiator full. No leaks.

Few wires the back to a runner.

Few wires the back to a runner.

Prrrrrrr.....

Took a bunch of internet searching along with some expert support to dial what should be the correct radiator. This is the 53 at the factory. That radiator I think was lost in the fires out for repair and they are sourcing one. 52 and 54 have the same on some.

Even though the radiator is the same the mounting is different on some. My water neck is 2 1/8 which I have yet to see on others which are smaller. The angle supports for the radiator are reversed on others.

Maybe the princes can tell is how many serials these two are apart?

Even though the radiator is the same the mounting is different on some. My water neck is 2 1/8 which I have yet to see on others which are smaller. The angle supports for the radiator are reversed on others.

Maybe the princes can tell is how many serials these two are apart?

During the courting period we are learning things about each other such as how not to change the oil. Jr enjoyed the show for I was laying under there for the plug pull.

Thought the filter was a sock type filter. Looks to be a paper carteridge that turned to mush taking out. The filters I am finding now seem to have a metal surround probably from the mush experience. Anybody have the filter and oring part #?

Drain plug has some sort of feltish gasket that doesn't look right. Need to figure that out as well.

Oil black but not bad considering.

Thought the filter was a sock type filter. Looks to be a paper carteridge that turned to mush taking out. The filters I am finding now seem to have a metal surround probably from the mush experience. Anybody have the filter and oring part #?

Drain plug has some sort of feltish gasket that doesn't look right. Need to figure that out as well.

Oil black but not bad considering.

Last edited:

Lots of sludge in the bottom. The oil pan probably caked as well when I get in there

j farm

Member

During the courting period we are learning things about each other such as how not to change the oil. Jr enjoyed the show for I was laying under there for the plug pull.

Thought the filter was a sock type filter. Looks to be a paper carteridge that turned to mush taking out. The filters I am finding now seem to have a metal surround probably from the mush experience. Anybody have the filter and oring part #?

Drain plug has some sort of feltish gasket that doesn't look right. Need to figure that out as well.

Oil black but not bad considering

That is one of the variants these dodge flatheads had but not on this one. That one is about 2" shorter and the lid uses a flat gasket and locks from the top with a tightener on the lid.

My setup the lid has an oring that seals then a split round clamp hinged in the middle for removal/install with a screw to tighten. Attached is a pic of mine I found online with the correct fram filter that crosses to Napa 1062 or Wix 51062.

We will find out this afternoon if a winner! Early days oil filters were an option on these motors fun fact I learned.

My setup the lid has an oring that seals then a split round clamp hinged in the middle for removal/install with a screw to tighten. Attached is a pic of mine I found online with the correct fram filter that crosses to Napa 1062 or Wix 51062.

We will find out this afternoon if a winner! Early days oil filters were an option on these motors fun fact I learned.

Last edited:

The filter fits this aluminum housing.

Cleaned all the sludge out. Part of the mess I made was because the filter drain was plugged. New gasket on the drain plug.

Filled with Mystery Oil and Valvoline racing 50wt zinc. Running some Ethanol free fuel and Mystery Oil as well. Motor runs and sounds amazing for how the car looks.

Makes oil pressure depending on the accuracy. Will do a other oil change before removal from chassis.

Cleaned all the sludge out. Part of the mess I made was because the filter drain was plugged. New gasket on the drain plug.

Filled with Mystery Oil and Valvoline racing 50wt zinc. Running some Ethanol free fuel and Mystery Oil as well. Motor runs and sounds amazing for how the car looks.

Makes oil pressure depending on the accuracy. Will do a other oil change before removal from chassis.

Last edited:

This will be a great restoration Brian. But of course, I would have a couple of comments. You can ignore/take seriously/laugh at as you please.

I was just thinking of the stress that body movement, vibration, etc would put on the radiator inlet, and wondering if anyone makes a bellows hose that short. Of course, as it heats up it will soften, but age will stiffen it up considerably.

And for another random thought...a story. I bought a very used Chevy bottled water delivery truck in Fresno CA. I was following it home while a friend drove it. On Hwy 97 about 10 miles south of Kalamath Falls, On a nice straight stretch, I noticed a black spot on the road. Thinking it was just a tar patch I didn't even swerve and ran over it. Not a tar patch, It went click click. I was a little confused then about 100 yards farther on the truck lost all its anti-freeze, more confusion. My friend felt the vibration and stopped on the side of the highway. The clicking black thing was a fan blade. The unbalance tore the water pump into many pieces before going through the radiator. Just another fun occurrence...as the tow truck was lifting the front I happened to be standing near the front tires. As it went up, the bottom of the tires swung inward about two inches.

The tow truck driver set me up with a great shop in K Falls who replaced the kingpins and put all the other stuff back together. It must have been a reasonable price, I don't have a clue what it cost, and I never had to do anything else to that rig. I put a dump bed on it and used it for about 8 years for filbert harvest.

SO, I applaud your choice of a NEW fan.

Could have said I'm a fan of the new fan.

I was just thinking of the stress that body movement, vibration, etc would put on the radiator inlet, and wondering if anyone makes a bellows hose that short. Of course, as it heats up it will soften, but age will stiffen it up considerably.

And for another random thought...a story. I bought a very used Chevy bottled water delivery truck in Fresno CA. I was following it home while a friend drove it. On Hwy 97 about 10 miles south of Kalamath Falls, On a nice straight stretch, I noticed a black spot on the road. Thinking it was just a tar patch I didn't even swerve and ran over it. Not a tar patch, It went click click. I was a little confused then about 100 yards farther on the truck lost all its anti-freeze, more confusion. My friend felt the vibration and stopped on the side of the highway. The clicking black thing was a fan blade. The unbalance tore the water pump into many pieces before going through the radiator. Just another fun occurrence...as the tow truck was lifting the front I happened to be standing near the front tires. As it went up, the bottom of the tires swung inward about two inches.

The tow truck driver set me up with a great shop in K Falls who replaced the kingpins and put all the other stuff back together. It must have been a reasonable price, I don't have a clue what it cost, and I never had to do anything else to that rig. I put a dump bed on it and used it for about 8 years for filbert harvest.

SO, I applaud your choice of a NEW fan.

Could have said I'm a fan of the new fan.

Today we sumited this mountain of a project and saw clearly the path forward. It's a project for sure!

Removed the remaining body panels which will only be useful as templates and revealed the bones which are decomposed to varying degrees.

Frame has some challenges but I have a path forward for the project. Removed the junkyard handy work. Plasma torch really a surgical instrument in the right hands. Wish I had them.

Removed the remaining body panels which will only be useful as templates and revealed the bones which are decomposed to varying degrees.

Frame has some challenges but I have a path forward for the project. Removed the junkyard handy work. Plasma torch really a surgical instrument in the right hands. Wish I had them.

Plan is to build a new 2 1/4" box frame with thicker wall using the existing frame as a template and the bolt ones for mock-up and measuring. Take it off one fit it on the new other.

The upper frame will be repaired replaced and fixed. When ready will cut the bottom uprights at the lower frame intersect and then right behind the front down support the hydraulic pump is on the lower frame. That contains all the bends curves and variables I can reuse.

The panels were load bearing. The flex on the frame is comical. Surprised is lasted all these years. I can also see how Tucker evolve the base earlier designs which is cool!

The upper frame will be repaired replaced and fixed. When ready will cut the bottom uprights at the lower frame intersect and then right behind the front down support the hydraulic pump is on the lower frame. That contains all the bends curves and variables I can reuse.

The panels were load bearing. The flex on the frame is comical. Surprised is lasted all these years. I can also see how Tucker evolve the base earlier designs which is cool!

2 1/4" tubing is very rare in long lengths in appears. I can get 90" or shorter so will continue the hunt. Might have to just replace and join at a frame intersect.

Safety inspector was on the job today assisting. The body screws are all removed. This is an interesting Tucker oops or ? Didnt improve much.

Power wash degrease then remove the organ removal begins.

Safety inspector was on the job today assisting. The body screws are all removed. This is an interesting Tucker oops or ? Didnt improve much.

Power wash degrease then remove the organ removal begins.

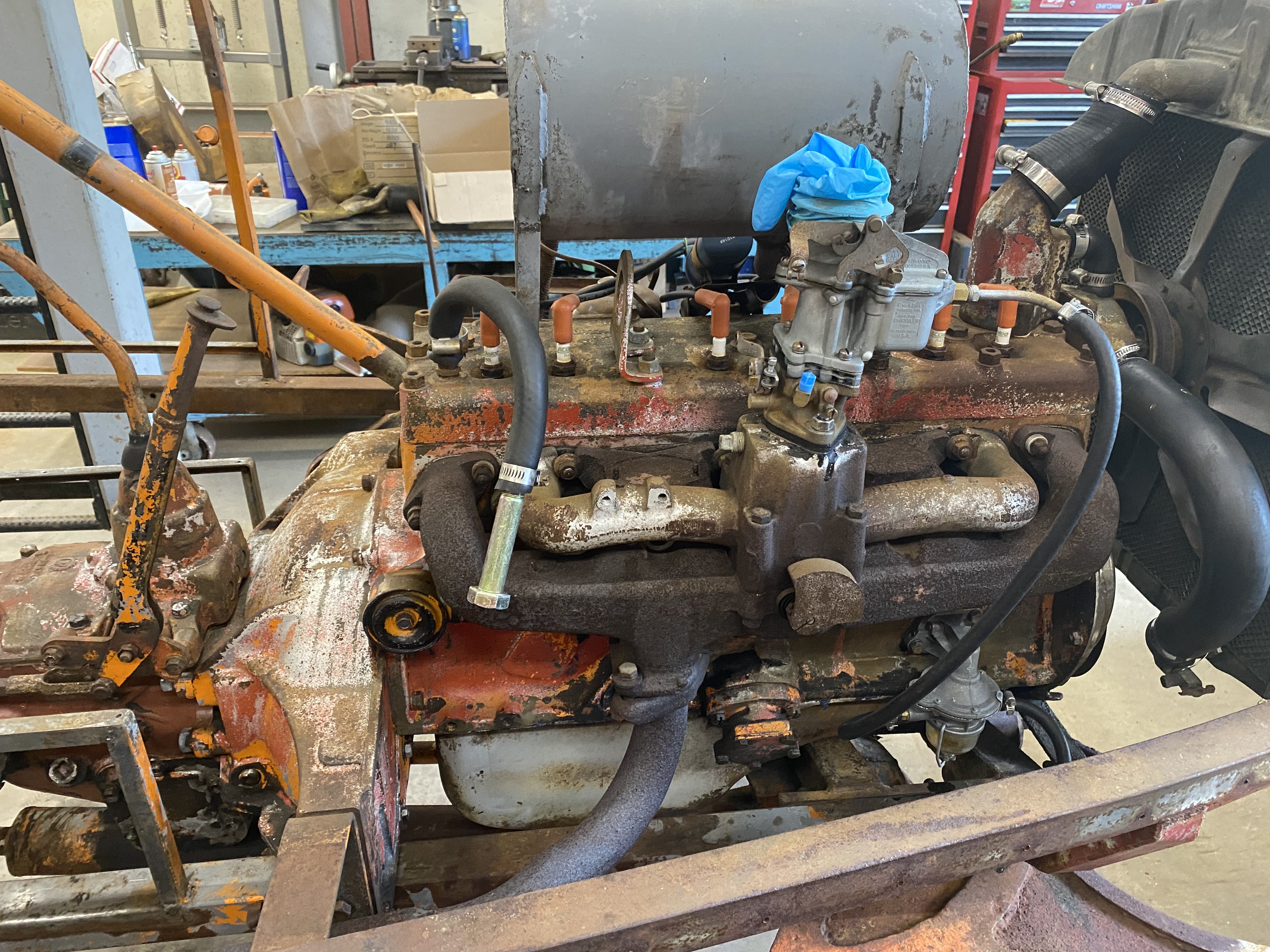

Ready for power washing before further disassembly.

Hoping I can slide the transmission out toward the rear then pull the motor.

Hoping I can slide the transmission out toward the rear then pull the motor.

Phase 1 wash complete. Need some more power so will try seam pressure tomorrow. The crud is stuck on good!

Found some orange under there and from what I can tell the motor was originally orange.

Found some orange under there and from what I can tell the motor was originally orange.

Measure twice think once. Good news the frame is common 14 ga 2". Where I measured in the back under all the gunk was 2 1/4" because of a scabbed on 1/4 repair.

Frame broken many places. Lower frame and uprights will be upgraded to 3/16 wall and the cross where the piston mounts 1/4. Table mount tabs will be thickened as well.

Got down to a base of silver/gray. Expert says silver with orange overspray would have been original.

Frame stock and table setup next along with hydraulic system removal.

Frame broken many places. Lower frame and uprights will be upgraded to 3/16 wall and the cross where the piston mounts 1/4. Table mount tabs will be thickened as well.

Got down to a base of silver/gray. Expert says silver with orange overspray would have been original.

Frame stock and table setup next along with hydraulic system removal.

Drained the hydraulic system and removed the hoses. Marinated a number of fasteners in pb blaster dressing.

Sourced the correct 4 blade fan. This confirms the longer one on it was junkyard.

2" 3/16 wall tubing for the lower frame. The 1 3/4" uprights will be replaced also 3/16 wall.

Table definitely not mounted center. Off 1/4 or so. Want to upgrade to 1/4" tabs but not sure Tucker left me enough room. Bolthead is tight to angle currently.

The oil pan has been off in life indicated by the blue gasket sealer and the trunion frame backer on backwards.

Wondering if the 90'defree rotation of the rear diff install is by design or solution once they realized they needed clearance

Sourced the correct 4 blade fan. This confirms the longer one on it was junkyard.

2" 3/16 wall tubing for the lower frame. The 1 3/4" uprights will be replaced also 3/16 wall.

Table definitely not mounted center. Off 1/4 or so. Want to upgrade to 1/4" tabs but not sure Tucker left me enough room. Bolthead is tight to angle currently.

The oil pan has been off in life indicated by the blue gasket sealer and the trunion frame backer on backwards.

Wondering if the 90'defree rotation of the rear diff install is by design or solution once they realized they needed clearance

Salavaged the rear hitch. Marty recounts that the old Tucker was always pulling the other cats out so needed to preserve that.

Straightened it out then cut it off. I always assumed this was solid stock but it appears to be c channel capped or tube then end capped and rounded. It looks like the hole was heated and punched but could drilled and wear from miles of uphill and down trailer trips. That or 12 gauge slugs...

Straightened it out then cut it off. I always assumed this was solid stock but it appears to be c channel capped or tube then end capped and rounded. It looks like the hole was heated and punched but could drilled and wear from miles of uphill and down trailer trips. That or 12 gauge slugs...

Snowy Rivers

Well-known member

These old cats certainly do get beat up over the years.

Gonna be all "MORE GOODER" When you get it finished....

(More Gooder...I remember that phrase from 1st grade...I had a buddy that always said that when something was gonna be "Better"

Strange at the things we remember for a lifetime...

MORE GOODER.....YUP

Gonna be all "MORE GOODER" When you get it finished....

(More Gooder...I remember that phrase from 1st grade...I had a buddy that always said that when something was gonna be "Better"

Strange at the things we remember for a lifetime...

MORE GOODER.....YUP

Got some of the driveshafts off and the tranfercase removed.

Freshwater from my power wash and coffee sludge drained out. Filled with mystery oil and fresh gear lube then spun the gears a bunch. Will rotate and marinate that mixture until I pull it apart.

Got the steering linkage off with a wedge heat tap repeat. Pin on the pivot to piston frozen as expected.

Reviewed enough pictures and experienced live support to determine what is oem and what is repair with the piston to frame mount. That little V shaped gusset caps is what will be used.

Freshwater from my power wash and coffee sludge drained out. Filled with mystery oil and fresh gear lube then spun the gears a bunch. Will rotate and marinate that mixture until I pull it apart.

Got the steering linkage off with a wedge heat tap repeat. Pin on the pivot to piston frozen as expected.

Reviewed enough pictures and experienced live support to determine what is oem and what is repair with the piston to frame mount. That little V shaped gusset caps is what will be used.

Strong Wednesday night. Took some surplus racks from work home to stash and organize parts and free the 73.

Brought in my support crew for the frame mock up and welding. Everything is in within spex of what we call "Tucker Tolerance".

Will final fit the motor eventually and triple check the transfer case mounts before final welding just in case.

Brought in my support crew for the frame mock up and welding. Everything is in within spex of what we call "Tucker Tolerance".

Will final fit the motor eventually and triple check the transfer case mounts before final welding just in case.

Removed the tie rods. They are amazingly straight for the life this cat had after the pontoonectomy and junkyard servitude.

Cut the piston mount tubes caps out of 1/4" flat plate for longer rot duration. From that I can tell this is how it was 6" with a 2" flat tapered up.

Below are pics of this cat and a similar vintage. Mine has been reinforced but you can see the original gusset which is real thin. Between the thicker wall tube and gusset this will be stronger and match oem asthetics.

Big thanks to the Tucker support network to confirm what is under the mess is what was oem to copy.

Big thanks to the Tucker support network to confirm what is under the mess is what was oem to copy.

Cut the piston mount tubes caps out of 1/4" flat plate for longer rot duration. From that I can tell this is how it was 6" with a 2" flat tapered up.

Below are pics of this cat and a similar vintage. Mine has been reinforced but you can see the original gusset which is real thin. Between the thicker wall tube and gusset this will be stronger and match oem asthetics.

Steering piston out and center pivot removed.

Pressed out the piston mount from the pivot. As expected the pivot was tight and the clevis was worn. This will all be rebushed and pinned.

The pivot to frame bushings are in ok shape but will be replaced. They used a 2.5" od x 1.25" id bronze hollow bronze stock. It's was cut to 1 1/4" and turned down to fit in the 1.5" housing leaving a 1/4" thick flange. These will be replicated to tighten back up to oem before mounting the pivot on the new frame. Thereare some numbers stamped in the flange.

Note the lack of weld in the pivot. Thinking they welded in place on the frame and no overheard skills were required for this job. Otherwise not sure why they didn't if bench welded?

Pressed out the piston mount from the pivot. As expected the pivot was tight and the clevis was worn. This will all be rebushed and pinned.

The pivot to frame bushings are in ok shape but will be replaced. They used a 2.5" od x 1.25" id bronze hollow bronze stock. It's was cut to 1 1/4" and turned down to fit in the 1.5" housing leaving a 1/4" thick flange. These will be replicated to tighten back up to oem before mounting the pivot on the new frame. Thereare some numbers stamped in the flange.

Note the lack of weld in the pivot. Thinking they welded in place on the frame and no overheard skills were required for this job. Otherwise not sure why they didn't if bench welded?