-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Did You Know ...

- Thread starter Doc

- Start date

In 2007, scientists made a stunning discovery off the coast of Alaska—a Bowhead whale was found with the tip of a 19th-century harpoon embedded deep in its neck. The harpoon fragment was identified as a bomb lance manufactured around 1890, revealing that the whale had survived a human hunting attempt over a century earlier. This extraordinary find provided rare, tangible evidence of the Bowhead whale’s incredible longevity. Known to be one of the longest-living mammals on Earth, Bowhead whales can live well over 100 years, with some estimates suggesting lifespans reaching up to 200 years. The embedded harpoon not only told a story of survival and resilience but also offered a glimpse into the past—an era of intense commercial whaling. Despite facing industrial-scale hunting, this whale managed to escape, heal, and continue its journey through Arctic waters for more than 100 years. The discovery serves as a powerful reminder of the deep history these majestic creatures carry within them, and the silent tales that swim beneath the surface of the sea.

Then he changed his name to Joe Biden and moved into the white house and ate 5 trillion.

shortarcflyer

Well-known member

I had heard of that a fews back but had forgotten about it. Interesting indeed.

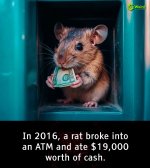

I don't see how that's possible. ATM money is in a safe. I can't see a rat breaking into a safe.

Pure silver has a similar effect

Almost

Well-known member

Found this.

pixie

Well-known member

Here is a link to an animation/cross section of the tunnel. It will have Two ! roundabouts underground but, sorry, no fish veiwing.

www.euronews.com

www.euronews.com

Inside Norway's project to build the world's deepest subsea highway

The Rogaland fixed link, or simply Rogfast, will be about 26.7km long and 390m at the deepest point under the sea when completed.

Obviously an artist's rendering.

Someone help me out here but at 1300 feet, isn't it getting pretty dark (dysphotic zone)?

I think that calculates to over 560 lbs per square inch pressure. Tough acrylic required.Obviously an artist's rendering.

Someone help me out here but at 1300 feet, isn't it getting pretty dark (dysphotic zone)?

I thought that also, it would be dark. but if they put a tunnel down there I suspect they would also add light so that you could truly enjoy the sights.Obviously an artist's rendering.

Someone help me out here but at 1300 feet, isn't it getting pretty dark (dysphotic zone)?

That would blind the fish I can hear Gretta Thornberg and PETA protestingI thought that also, it would be dark. but if they put a tunnel down there I suspect they would also add light so that you could truly enjoy the sights.

Germany makes self-healing concrete that repairs itself in the rain

German civil engineers have created a revolutionary self-healing concrete that can repair its own cracks when exposed to rainwater, potentially ending the costly cycle of road and building repairs. This breakthrough combines advanced cement chemistry with microencapsulated healing agents, allowing the material to “heal” within days of damage appearing.

The secret lies in tiny capsules embedded in the concrete mixture. These capsules contain a limestone-producing bacteria that stays dormant until water seeps into a crack. When rain penetrates the damaged area, the bacteria activates, feeds on calcium lactate inside the capsule, and produces limestone — effectively sealing the gap from within. This creates a watertight repair that strengthens over time.

Germany’s highway system, famous for its high speeds but plagued by seasonal cracking, is already testing sections made with this concrete. Early trials show up to 90% of surface cracks vanish within two weeks, even under heavy truck traffic. This could mean far fewer maintenance closures and billions saved in public infrastructure budgets.

The environmental benefits are also significant. Traditional concrete repair requires energy-intensive manufacturing and frequent transport of new materials. By extending the lifespan of structures, self-healing concrete could slash cement production — a major contributor to CO₂ emissions — by as much as 30% over the next decade.

Urban planners are especially excited about applying this in flood-prone areas, where water damage to roads and bridges is a constant problem. The material’s water-triggered repair mechanism means it can actually become stronger after storms, instead of weaker.

If scaled globally, this invention could fundamentally change how cities build and maintain infrastructure — shifting from a repair-first mindset to a self-sustaining one.

Scotland has made a major leap in renewable energy by deploying the most powerful tidal turbine ever built. Anchored in fast-flowing waters, this engineering marvel converts the kinetic energy of ocean currents into clean electricity. At full capacity, it can power over 2,000 homes and prevent 2,200 tonnes of CO2 emissions annually.

Unlike wind or solar, tidal energy is predictable -it can be calculated years in advance based on the moon's gravitational pull. This makes it a highly reliable source of green energy that can supplement other renewables.

The turbine's installation marks a milestone in the shift toward sustainable power solutions. If replicated globally, tidal technology could supply millions of homes with stable, carbon-free electricity, helping fight climate change while preserving marine ecosystems.

Found on FB. I hope it is true.

==================

Scientists have discovered a vast underground reservoir of natural hydrogen—possibly containing trillions of tons—that could transform the global energy landscape. Often called “gold hydrogen” or geological hydrogen, this rare resource offers a clean, naturally occurring alternative to conventional hydrogen production.

Unlike traditional methods, which are energy-intensive and carbon-heavy, gold hydrogen is generated naturally deep underground through reactions between iron-rich rocks and water. It can be extracted in a similar way to natural gas, but without harmful emissions.

Key advantages:

* Produces no CO₂—burns clean, releasing only water vapor

* Immense reserves—enough to supply the planet for more than 1,000 years

* Scalable and cost-efficient

* Potential to reshape the global hydrogen economy

If developed on a commercial scale, gold hydrogen could power homes, industries, vehicles, and even space exploration—offering a major leap toward a sustainable, low-carbon future.

==================

Scientists have discovered a vast underground reservoir of natural hydrogen—possibly containing trillions of tons—that could transform the global energy landscape. Often called “gold hydrogen” or geological hydrogen, this rare resource offers a clean, naturally occurring alternative to conventional hydrogen production.

Unlike traditional methods, which are energy-intensive and carbon-heavy, gold hydrogen is generated naturally deep underground through reactions between iron-rich rocks and water. It can be extracted in a similar way to natural gas, but without harmful emissions.

Key advantages:

* Produces no CO₂—burns clean, releasing only water vapor

* Immense reserves—enough to supply the planet for more than 1,000 years

* Scalable and cost-efficient

* Potential to reshape the global hydrogen economy

If developed on a commercial scale, gold hydrogen could power homes, industries, vehicles, and even space exploration—offering a major leap toward a sustainable, low-carbon future.