Those look like turbos on the end of the pipes. If in good condition they qualify in place of arrestors.The USFS approved spark arrestor cert might be the tough one

-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1989 Tucker 1644c

- Thread starter 1boringguy

- Start date

1BG,

That sounds fantastic. No other way to put it...

That sounds fantastic. No other way to put it...

1boringguy

Well-known member

If I put the end caps in the exhuast pipes I think I can get the sprinkler heads spinning about 20 rpm. That'll still be a few orders of magnitude less than an actual turbo, but I think it'll still have that 'turbo whistle ', so maybe I can sell it as a new 'Elon Musk Design '. That's gotta be good, right?Those look like turbos on the end of the pipes. If in good condition they qualify in place of arrestors.

1BG,

That sounds fantastic. No other way to put it...

It's all about the exhaust

Pun aside though, I am happy about the way the engine has turned out. Not that a SnoCat needs all that, but like I told PP when she asked, "well how much horsepower do you really need ....", "just a little more than I'm wanting at any given moment."

1BG,If I put the end caps in the exhuast pipes I think I can get the sprinkler heads spinning about 20 rpm. That'll still be a few orders of magnitude less than an actual turbo, but I think it'll still have that 'turbo whistle ', so maybe I can sell it as a new 'Elon Musk Design '. That's gotta be good, right?

It's all about the exhaust

Pun aside though, I am happy about the way the engine has turned out. Not that a SnoCat needs all that, but like I told PP when she asked, "well how much horsepower do you really need ....", "just a little more than I'm wanting at any given moment."

There's a great aviation saying about power that I absolutely subscribe to, and I think you'll like it as well. "A lot is good, more is better and too much... is just about right".

more power Scotty, more power!!!

Snowy Rivers

Well-known member

You will likely have enough to break stuff if you work at it.....If I put the end caps in the exhuast pipes I think I can get the sprinkler heads spinning about 20 rpm. That'll still be a few orders of magnitude less than an actual turbo, but I think it'll still have that 'turbo whistle ', so maybe I can sell it as a new 'Elon Musk Design '. That's gotta be good, right?

It's all about the exhaust

Pun aside though, I am happy about the way the engine has turned out. Not that a SnoCat needs all that, but like I told PP when she asked, "well how much horsepower do you really need ....", "just a little more than I'm wanting at any given moment."

It's all about having enough to get the job done...plus sounding BAD AZZ....

What are the specs on the cam ???

I have been snooping around for a cam choice for my 406 SMALL BLOCK CHEVY that's going in the FrankenCat

I decided on using Vortec heads ...and these (in stock trim) are only good for about .450" lift before the spring retainers hit the valve stem seals.... (NO need to spend lotsa buckos on head mods)

The Tucker sounds great.... Actually pretty mellow

This limits cam choices a bunch

Snowy Rivers

Well-known member

Yeah....too much is fine...IF the operator knows when to get the boot off the skinny pedal...BEFORE CHIT BREAKS...1BG,

There's a great aviation saying about power that I absolutely subscribe to, and I think you'll like it as well. "A lot is good, more is better and too much... is just about right".

1boringguy

Well-known member

SR,You will likely have enough to break stuff if you work at it.....

It's all about having enough to get the job done...plus sounding BAD AZZ....

What are the specs on the cam ???

I have been snooping around for a cam choice for my 406 SMALL BLOCK CHEVY that's going in the FrankenCat

I decided on using Vortec heads ...and these (in stock trim) are only good for about .450" lift before the spring retainers hit the valve stem seals.... (NO need to spend lotsa buckos on head mods)

The Tucker sounds great.... Actually pretty mellow

This limits cam choices a bunch

This is the cam that I used. Of course a stroker handles/needs more cam than a standard configuration, and I'm convinced that the PF4 efi helps smooth things out as well. Some reason I thought we ended up closer to .500 lift but I see that's not the case. Again, haven't had it out in the field yet, but I'm liking it so far.

Last edited:

1boringguy

Well-known member

Probably everyone knows this but me, but I'll share it just in case anyone else reads this at some point who doesn't.

I can get all the engine gauge functions on the tablet Edelbrock supplied with the PF4 EFI system, or you can download the app to your phone and sync it, and then have them there. I put the tablet on the dash with a dash mount holder and have used it thus far, but l want the gauges in the cat to all function properly as well. The efi ecm does away with the need for much of the old engine control electronics, and the supplied wiring harness has a wire for 'tach'. So I wired it up to the tach, but no banana.

After a little goggle search I found this explanation for someone else who had the same problem;

So connected the wire from the old school tach to the neg post on the coil and it's back in bussiness.

I can get all the engine gauge functions on the tablet Edelbrock supplied with the PF4 EFI system, or you can download the app to your phone and sync it, and then have them there. I put the tablet on the dash with a dash mount holder and have used it thus far, but l want the gauges in the cat to all function properly as well. The efi ecm does away with the need for much of the old engine control electronics, and the supplied wiring harness has a wire for 'tach'. So I wired it up to the tach, but no banana.

After a little goggle search I found this explanation for someone else who had the same problem;

So connected the wire from the old school tach to the neg post on the coil and it's back in bussiness.

Last edited:

1boringguy

Well-known member

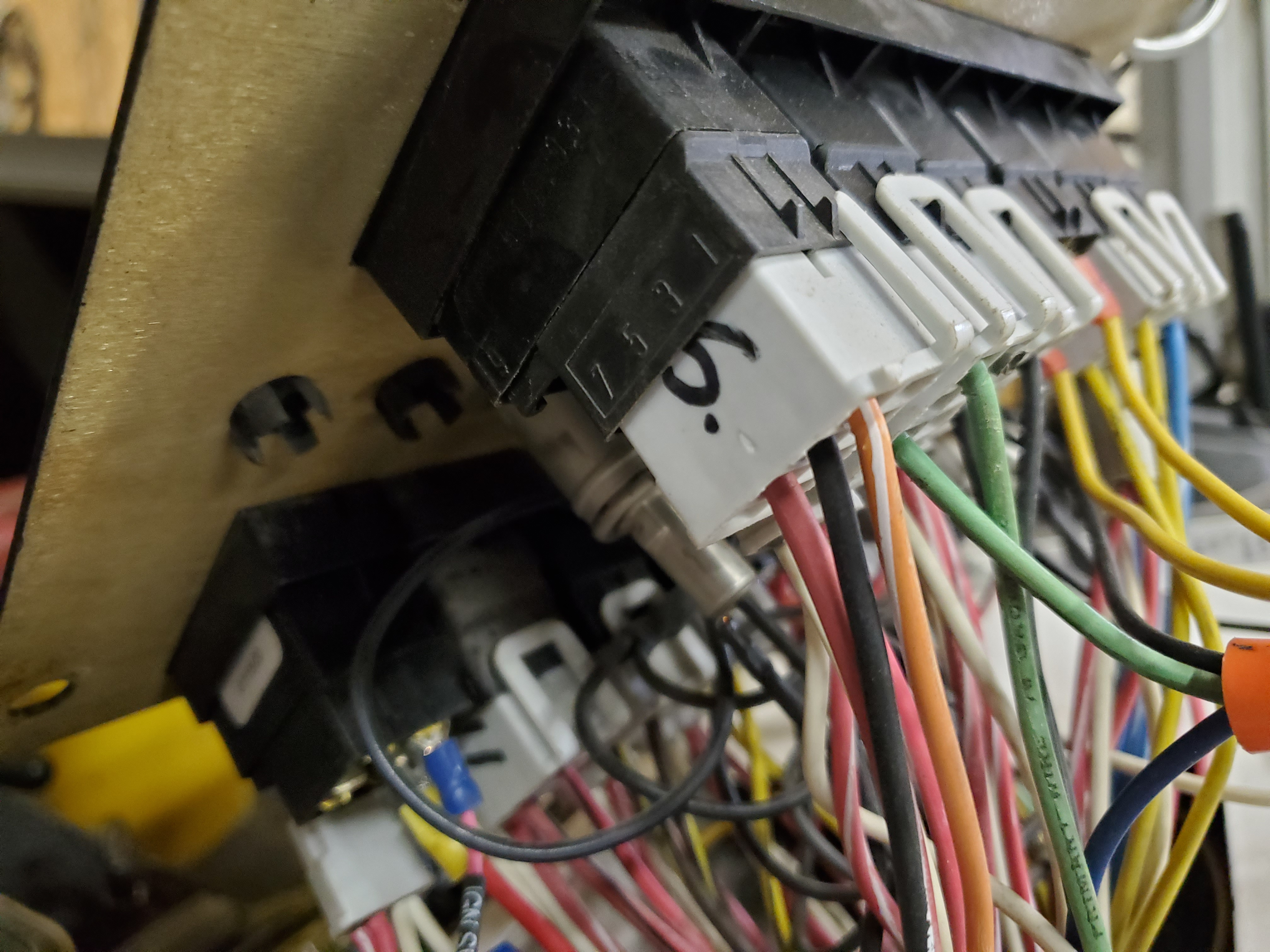

Couple more check marks the weekend.

Alignment, like Tuckers instructions admit, sounds more complicated than it is. They say to pull measurement from the rear of the frame, but that's assuming that the frame bends, bed, or whatever, was all made square. Anyway I decided to just square up to the main frame and measure from that.

Adjusted the parking brake, but no exciting pics of that.

And added some power points, gotta keep the electronics running you know. Since the cat has a battery isolator and two batteries, I've wired so that the music, device charging, cb radio, ect, draw from the second battery, so if you sit around the camp fire playing music all night or something, the starting battery is always full charge.

Alignment, like Tuckers instructions admit, sounds more complicated than it is. They say to pull measurement from the rear of the frame, but that's assuming that the frame bends, bed, or whatever, was all made square. Anyway I decided to just square up to the main frame and measure from that.

Adjusted the parking brake, but no exciting pics of that.

And added some power points, gotta keep the electronics running you know. Since the cat has a battery isolator and two batteries, I've wired so that the music, device charging, cb radio, ect, draw from the second battery, so if you sit around the camp fire playing music all night or something, the starting battery is always full charge.

1boringguy

Well-known member

Had a minute so did a couple things on my 'interior' list.

All the panel switches are numbered and correspond to the numbered fuse panel. Wiring that plugs into each switch is also numbered and is there even if not used in my application. I had several empty/blocked switch spots, so I ordered a few switches from Tucker (originals still available) to fill the holes, instead of the blanks, and for use in the future. Probably need to add about 33 more led lights to keep up with Wbj1

I called Tucker, but they didn't have a wiring diagram applicable to my machine, so I started heating a wire at the numbered switch and looking for the outcome with a test light. Some I couldn't find anything heated, and other places I still have wires that I can't determine their function, but here's what I did find.

1. Low beam head lights, tail lights, and unused wire overhead front of cab interior.

2. Unused, overhead front of cab interior, and front of hood at the frame.

3. Could not find.

4. Cargo light.

5. High beam headlights.

6. Heater blower.

7. Wipers.

8. Could not find. Someone after factory, wired this to aux blower in cab.

9. Unused, rear cab door overhead interior.

10. Overhead interior above back seat center.

11. Electric fuel pump.

12. Unused plug near backup alarm, rear of frame exterior, and front of hood on the frame.

Aux 1. Not used.

Aux 2. Not used.

Also repainted the seat frames. I swear these mechanical spring ride Bostrom seats must weigh 50 pounds each.

All the panel switches are numbered and correspond to the numbered fuse panel. Wiring that plugs into each switch is also numbered and is there even if not used in my application. I had several empty/blocked switch spots, so I ordered a few switches from Tucker (originals still available) to fill the holes, instead of the blanks, and for use in the future. Probably need to add about 33 more led lights to keep up with Wbj1

I called Tucker, but they didn't have a wiring diagram applicable to my machine, so I started heating a wire at the numbered switch and looking for the outcome with a test light. Some I couldn't find anything heated, and other places I still have wires that I can't determine their function, but here's what I did find.

1. Low beam head lights, tail lights, and unused wire overhead front of cab interior.

2. Unused, overhead front of cab interior, and front of hood at the frame.

3. Could not find.

4. Cargo light.

5. High beam headlights.

6. Heater blower.

7. Wipers.

8. Could not find. Someone after factory, wired this to aux blower in cab.

9. Unused, rear cab door overhead interior.

10. Overhead interior above back seat center.

11. Electric fuel pump.

12. Unused plug near backup alarm, rear of frame exterior, and front of hood on the frame.

Aux 1. Not used.

Aux 2. Not used.

Also repainted the seat frames. I swear these mechanical spring ride Bostrom seats must weigh 50 pounds each.

Last edited:

1boringguy

Well-known member

Well everyone who has looked through the SV2022 has probably already noticed that I managed to get running up and down the mountain the last couple days of the Sun Valley get together.

I still have a number of small items to finish up, but was thankful to get to test the general mechanical soundness before the end of the snow year around here. The take away from those two days is that I may want to change some springs in the trans valve body that controls the shift points, and I have a feedback through the sound system and the auxiliary battery. Not to big of issues. Anyway mostly moving forward with it, and hope to have a long season next year.

I'll post some more as I finish up some things like the exhaust, but for now just the proverbial before and after pics.

I still have a number of small items to finish up, but was thankful to get to test the general mechanical soundness before the end of the snow year around here. The take away from those two days is that I may want to change some springs in the trans valve body that controls the shift points, and I have a feedback through the sound system and the auxiliary battery. Not to big of issues. Anyway mostly moving forward with it, and hope to have a long season next year.

I'll post some more as I finish up some things like the exhaust, but for now just the proverbial before and after pics.

1boringguy

Well-known member

well, at least it's not green. (somebody had to say it)

Jack,

You killed it! Your machine looked awesome and backed it up by performing great! You should be proud!!

Cidertom,

Green is one thing. Painted green by PP is way better!!!

You killed it! Your machine looked awesome and backed it up by performing great! You should be proud!!

Cidertom,

Green is one thing. Painted green by PP is way better!!!

Red White Blue and Army colored reunion. SV 2023!

1BG,

I agree totally with The Infamous WBJ1 (scary thought, right there). But he's right; "White Lightning" is an awesome machine and you should be very proud of what you accomplished. It looks great and performs even better. My sincere congratulations!

I agree totally with The Infamous WBJ1 (scary thought, right there). But he's right; "White Lightning" is an awesome machine and you should be very proud of what you accomplished. It looks great and performs even better. My sincere congratulations!

1boringguy

Well-known member

Thanks all for the compliments. I'm happy not to have been 'that guy' having to be towed back to the trailer.

Agree with TA, hope to see more people's projects running around on the snow next year.

Agree with TA, hope to see more people's projects running around on the snow next year.

TalleyHo

Active member

I became a fan of lockers when I lost a track and couldn't make it up an icy slope. They don't steer when locked in at all but as you said, they are great for last option available scenarios.WBJ1,

Not the expert here either but listening and thinking. Jeep'n vs Snowcatting might not be quite as drastic of a mentality/experience shift as say driving to flying, but along the same line I think. Lots of factors play into what one thinks is climbable at a given moment; machine, snow conditions, oneupmanship (particularly if there's someone around to hold your beer), ect. Watching some videos of personal cats playing in the snow gives a glimpse of what realistic expectations look like I think. The second video is of, I believe, ff participant wakeup call's 1642. If you watch it closely you can see the rear tracks stop intermittently, indicating open diff functioning. I'm wondering if any of the Colorado guys have lockers on their Tuckers who might share experience?

And what does a go anywhere (or as close as it gets) cat look like? Probably something like this ?

For me, I'm thinking of it like the jeep I guess. I'm not a rock crawler so I don't use them much, but when I do need them it's damn nice to have them. ?

And confidence factor in your equipment when you're 15 miles from the truck counts for something.

TalleyHo

Active member

Really cool pic with snow on the grousers. Snow leopard...Well everyone who has looked through the SV2022 has probably already noticed that I managed to get running up and down the mountain the last couple days of the Sun Valley get together.

I still have a number of small items to finish up, but was thankful to get to test the general mechanical soundness before the end of the snow year around here. The take away from those two days is that I may want to change some springs in the trans valve body that controls the shift points, and I have a feedback through the sound system and the auxiliary battery. Not to big of issues. Anyway mostly moving forward with it, and hope to have a long season next year.

I'll post some more as I finish up some things like the exhaust, but for now just the proverbial before and after pics.

View attachment 147505

View attachment 147506

1boringguy

Well-known member

TalleyHo,Really cool pic with snow on the grousers. Snow leopard...

Snow Leopard ....... yea I like that. Although I'm sure a Snow Leopard would be highly insulted by something being likened to itself, that only goes 10mph.

I reckoned 'White Lighting' stuck because like most Burt Reynolds characters, I'm highly unpolished.

761643

New member

Finally found a post with your user name. Had some questions on the sprocket hub you built. I have the same problem with my 1976, 1643 Tucker, Serial # 3763238. My Tucker has a 5 1/8” pitch. 1- was the pitch the same on the square tooth sprocket you bought as on the pointed tooth sprocket? 2- if the pitch is greater than 5 1/8” centerline, how does that effect the alignment on the track trousers? Any info would be helpful. ThanksNot sure when it was remanufactured, it was sold to Aspen Ski In 1981 but then was bought by Snoqualmie Ski area before I got it.

Snowy Rivers

Well-known member

Just my 2 cents..Found another problem. Glad to find this one in the shop and not a failure 20 miles out on a trail. I'm thinking maybe I'll have to just cut a section out of the 5th wheel plate, maybe a foot square, and replace that whole area. Thought about v-ing it out, welding it, and then cutting a donut out of 1/2" plate and over laying that on the bottom side. The metal right around the bushing has got to be fatigued right? Anyone see this before? What was your solution? Also rear 5th wheel has about .015 wear in the male and female parts, so needs to get cut and bushing installed anyway.

If I were doing it...I would cut off that entire plate and replace it with fresh metal.....

The old part has been flexed and tweaked a LOT over the years....Fatigue has taken its toll.

A repair could get you by for a while....But very likely the thing will break again.....

Build your new part and remove all stress risers (Sharp corners and areas that cracks can start)

On the side of the plate where the boss has the grease zirk....Is there room to add a piece of 5/8" plate that would go around the boss and lap over the flat plate ?????

That boss sitting where it does has zero support and has been flexing.

A "Doubler" plate will spread the load out over a wide area and stop things from cracking.

Skip weld the doubler plate along the edge and around the entire area......You don't need tons of weld.....just need to keep that boss from bending the plate like a paper clip.....

Machine a fresh boss OR....KEEP IT SIMPLE

As you mentioned V out the crack (Drill 5/16 hole at each end of the crack to stop propagation ) then weld up.

Cut the doubler plate.....It can be more of a triangle shape...just make the one area rounded behind the boss.

Burn a clean hole in the doubler that will just fit over the boss......Chamfer the inner edge of the doubler plate so it will sit down snug over the original weld and lay flat against the old plate

Skip weld around the periphery....DO NOT WRAP THE CORNERS....WELD THE LAST BIT AND RUN THE WELD OUT ONTO THE PLATE...

Wrapping the corners IS WHERE IT WILL CRACK.

Skip weld the edges so both pieces are attached together....do 3 skip welds on the boss where it protrudes through the doubler.

Should be fine.....Smooth all edges of the original plate especially the area where the crack was.....

Many times when parts break the issue needs to be looked at carefully to see WHY IT BROKE...

There are times that simply adding metal in one area will vector the stress and things will break somewhere else.

I do not believe that this is one of those times.....That boss has been wiggling the plate to a fro until it gave up..

The old saying in the racing world...."If it ain't moving, something's breaking" is good advice....Welded trailer frames break.....they can't flex....Hence the reason that frames are riveted, bolted or in some cases huck bolts are used....

The issue on the tucker is a simple case of no support on the boss/plate.

YOUR IDEA OF A DONUT...just take it a lot farther and spread that load out over a much wider area....

Having a little bit of movement in the bushings will allow things to Wiggle a bit....The ain't moving somethings breaking things.

Don't get extremely worried about a few thou of clearance....Room for grease ya know...

Attachments

Last edited:

Finally found a post with your user name. Had some questions on the sprocket hub you built. I have the same problem with my 1976, 1643 Tucker, Serial # 3763238. My Tucker has a 5 1/8” pitch. 1- was the pitch the same on the square tooth sprocket you bought as on the pointed tooth sprocket? 2- if the pitch is greater than 5 1/8” centerline, how does that effect the alignment on the track trousers? Any info would be helpful. Thanks

PM Rob directly. He may not see your question here. And this section is typically pretty quiet during the summer months.

I came across this post in search, looking for information on what torque converter was used by Tucker for the LH318 engine. The fellow (John) who is building the 727 is adamant that the torque converter is matched to the cam profile in the LH318 Industrial engine, and John is after me to figure it out.The Allison tranny...for sure is in a class all by itself.

As mentioned....the original diesels were tough on trannies.....

The TH400 and to a little bit lesser degree the TH350 can stand a beating IF THEY ARE BUILT RIGHT.

Shift kits (Transgo is my fav) are a must have to ensure longevity.

As mentioned...KEEPING THE OIL COOL is paramount...

The 727 TF is not a bad box....but in stock trim the shift timing was very poor.....(Seems Mopar engineers were more interested in making the big land yacht's operate smoooooooth and not shake grandma in the least)

The mushmellon shifts caused many premature clutch and and band failures....

I was working in a Mopar shop in the early 70's and the parade of big sleds with toasted trannies seemed way too common.

Shift calibration was the biggest issue.

The aftermarket companies came to the rescue and solved most of the ill's of the various gear boxes.

The TH400 has always been regarded as "Bomb proof" Well, somewhat would be my opinion. The 400 has been installed in some very large rigs over the years...and they have done well.....

Still...the big three auto makers never seem to include the tranny in their thinking when they added more power.....

Dodge came out with the 6.7 around 2006/2007 and the auto tranny was a joke.

If you were serious about working the big 6 cyl oil burner....you needed a tranny shop close by.

Later years have seen a lot of improvements......But the gear boxes always seem to be the last part of the equation to catch up.

The older Allison AT 545 IS A BEAST by any definition .....Firm shifting and made to deal with very demanding loads.....

The internal parts are very robust and there is really no standard pickup/car tranny that compares..

Then we can look at one of the worst gear boxes produced in recent history....The GM 700R4 (4L60 OR 4L60E)

There area always service bulletins that come out on just about every design....A book/binder with a modest amount of pages was is common...The 700R /4l60 THE LAST TIME I BOTHERED TO COUNT....HAD service bulletins that filled a shelf about 8 feet long in the office......

Design errors and corporate bean counters contributed to most of these.

The current crop of stuff from the manufs are outside my wheel house as I have not followed the trannies since the addition of the 6 through 10 speed models.

The old stand by boxes for sure can be upgraded to handle some pretty tough jobs.....Just always look at keeping the oil temp in check...

Another point

Just because you have a particular model of gear box does not always mean much....What engine was bolted up front of it ??? This will often spell out what clutch packs are/were used as well as a host of other differences in the inner workings.

4 pinion planets or 5...A heavier duty application most likely will have more robust parts.

Number of clutch friction plates......Lighter duty can/will have less friction plates in the clutch packs.....

Some light duty components were made of aluminum instead of steel....

The aftermarket has provided a wide variety of goodies to make your tranny better....

Heavy duty planet carriers

More robust sun shells

Better friction plates as well as better steel plates (Go between the frictions) and more of them.

Better bands with stronger anchors and better friction materials.

Higher output oil pumps.

Better bushings and thrust bearings.

In some cases....stronger input/output shafts.

Various little gizmos to stop case wear on some models..

An entire industry sprang up to deliver shift kits to fix various issues of internal oil leaks, shift timing, oil volume to the servos and on it goes.

You want an entirely manual (Select shift) No worries....it's available.

Governor calibration

Throttle pressure fixes

Vacuum modulator modification...

Complete valve bodies...yup, these too.

Torque converters of all sizes and stall speeds

Welded turbine and pump blades .....

If the box has a lockup converter.....Better lockup clutches and in some multiple disc clutches.

The original lockup clutch was simply a device to help get the "CAFE" Numbers up by eliminating the slipping in the converter at cruise speeds...... (Corporate average fuel economy)

THESE CLUTCHES ONLY OPERATED AT LIGHT TORQUE CRUISING SPEEDS....and could not hold heavy torque loads....and were released when the throttle was increased much....

The later boxes have multiple disc lockup clutches and in many cases are engaged at various times and shift points...especially with the diesels...

Beefier is better if you are going to get rough on things...or push things.

You can't have too tough of a tranny. Build the damned thing stout and set it on KILL.....Build it as strong as you can....If there are parts to make it twice as strong as you need...GET THEM....This stuff is pennys compared to what it costs to get your cat dragged out of brush 20 miles in..

More clutches do not hurt anything....just cost the OEM more $$$ and if the engineers say 3 clutch plates in 3rd gear is fine...they do it.

5 clutches are far better and will last a lot longer......

A needle bearing thrust assembly....far better than a plastic thrust washer, or even a steel backed bronze washer.

This subject can go on for pages and pages......but the bottom line.....IF YOU VAN GET A BIG HERKY BOX IN YOUR CAT....DO IT

The only real downside to the big Allison is parasitic drag.....Not worth worrying about in a rig that goes 12-15 mph

But the herky parts inside can give piece of mind to the owner while out in the back country....

Or maybe if anyone had the cam specs torque curve I could use that info?

John has been building up transmissions for 50 years and just retired, so I just say, yes sir!