It's been a quiet week on FF in the snow cat area! I guess it's been hot all over, like really hot! You don't really want to work or take pictures when it's that hot. But tonite, I forced myself to take pics of the work I did this week (so little, but every baby step forward is one step closer to a running SW-48).

Pic #1 -- reinstalled engine covers and rad for mock up. Notice the interior color, called pistachio. I like it, kinda looks like the interior of the M113.

Pic #2 -- to get better seal on the engine covers, welded some brackets to fit over the lip on the hull. Works OK, but if I had to redo, would make the offset bigger, like 1/2" instead of 1/4".

Pic #3 -- with some scrap stainless steel, went to the airport machine shop (got a free pass this week) and used the shear and the brake to bend the plate to replace the rusted and messed up drive shaft cover. Notice also fresh coat of paint inside the drivers habitacle. Also, just because I could, made a new clutch pedal with checker plate aluminum. Think I'll do the same for the accelerator. Still have to make the new foot rest on the accelerator side, when I sand blasted it, it just fell off

.

Pic #4 -- cleaned the transmission, flushed it, and refilled it. You can see how either it's not the original tranny or someone broke the supports for it and welded some on the bell housing. I also cleaned all the swamp crap from the bottom pan.

Pic #5 -- doesn't look like much, but I couldn't adjust the clutch last year so while everything is open, tried again (much easier without gloves and parka). Couldn't get a good clutch adjustment (was testing it with tranny in gear and trying to turn the drive shaft while the pedal was pushed down). Finally remove the connecting rod to find it was used and a bit too long. Solution, cut it, thread it and reconnect with 1/4' plate steel. Now I have an adjustment if ever it starts to not disengage the motor again.

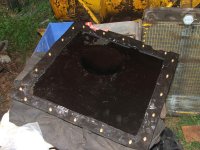

Pic #6 -- a good shot showing the gasket (nitrile 1/8") used to seal the cover of the differential. I liked the stuff so much, went a bought more to do the two sprocket "flower pots". Dude is selling me his scraps at 1/2 price so I guess it ain't too bad. For those in the Ottawa area, it's Hydro Silica Gasket Cutting at the corner of Innes and Bantree but on Newmarket. Great place for all gasket materials. Just down the road, Ottawa clutch and brake, great place for reshoeing anything.

I hope this puts everyone in a posting mood, even in this intense heat. I can't complain, at least we're having a summer this year. The last three have been just rain, rain, and more rain.

Oh, and I didn't take pics, but I punched two more length of conveyor belting (I'm not rich enough to buy it already punched) to get ready for track #2. I'm so glad my wife is busy with work in the evenings and the kids are playing with their friends, leaves me all the "cool" time to work on my baby. I already have two contracts for plowing next winter. This has to work, otherwise, I'll be doing it with the snow blower...ouch.

This week is hot!!!

This week is hot!!! . Notice first bolt on block, had to burr it down a bit so the nut would turn...DOH!

. Notice first bolt on block, had to burr it down a bit so the nut would turn...DOH!

Hope it works....

Hope it works....

.

.

. That plate in the shape of an upside down U was also found in the Lynx (Don if you know the designation number I don't remember) like the M113, but with the engine (diesel V6) in the back, drive shaft went through the driver's/crew commander/observer compartment with the diff in the front. If ever one of the u-joint gives, this prevents the drive shaft from making hamburger out of your legs....

. That plate in the shape of an upside down U was also found in the Lynx (Don if you know the designation number I don't remember) like the M113, but with the engine (diesel V6) in the back, drive shaft went through the driver's/crew commander/observer compartment with the diff in the front. If ever one of the u-joint gives, this prevents the drive shaft from making hamburger out of your legs....

...Well maybe not just yet...hahaha

...Well maybe not just yet...hahaha

hmmmm, I wonder what she wants now???

hmmmm, I wonder what she wants now???