-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OTB-Bombi! Let the Jury Begin

- Thread starter OTB

- Start date

Well, tranny is almost done and some of the motor parts are painted. Just waiting for the mechine shop and the power train will be ready to rock!

Attachments

Well, uncovered a huge amount of rust and I have to say.....getting a little worried!

Attachments

Snowy Rivers

Well-known member

Rust is always a concern.

Can you cut out the bad stuff and graft in new material ???

Can you cut out the bad stuff and graft in new material ???

I have found so much, I think I am just going to start from scratch. And replace almost everything.....maybeRust is always a concern.

Can you cut out the bad stuff and graft in new material ???

I will try and reload them. Sorry about that!OTB, your photos are quite large and some folks will not open them, because of that. Do you have the ability to reduce them?

Attachments

Snowy Rivers

Well-known member

I feel your pain.....

I went through the rust thing myself....But it was inside the differential that had filled up with water and ruined all the bearings.

In looking at the piccy's it does look like the frame is pretty sad..

Was the machine just sitting in the elements ????

Almost looks like a serious attack of "Salt poisoning"

I went through the rust thing myself....But it was inside the differential that had filled up with water and ruined all the bearings.

In looking at the piccy's it does look like the frame is pretty sad..

Was the machine just sitting in the elements ????

Almost looks like a serious attack of "Salt poisoning"

Well, the fella I bought it from had it inside I think and tried to take care of it, but the previous owners to him really let it go. The frame I think could be saved, but with all the time I'll have into it, I think I am just going to start from scratch.I feel your pain.....

I went through the rust thing myself....But it was inside the differential that had filled up with water and ruined all the bearings.

In looking at the piccy's it does look like the frame is pretty sad..

Was the machine just sitting in the elements ????

Almost looks like a serious attack of "Salt poisoning"

This is by fare the worst rust I have ever dealt with. Just crazy!

Snowy Rivers

Well-known member

If you have enough good metal so you can copy the parts for patterns your set.

Any places that have cracks you can figure out where the stress risers were and make things better....

Good luck....Not always the destination.....but it's the journey that counts......

Any places that have cracks you can figure out where the stress risers were and make things better....

Good luck....Not always the destination.....but it's the journey that counts......

If you have enough good metal so you can copy the parts for patterns your set.

Any places that have cracks you can figure out where the stress risers were and make things better....

Good luck....Not always the destination.....but it's the journey that counts......

Yes sir! Well, the jury's back in the verdict is in!

Literally starting from the frame and going to go all the way out!

On a comical note, I posted a video on Facebook last night about how much rust was on this machine.

On a comical note, I posted a video on Facebook last night about how much rust was on this machine.The next day I called Minnesota Outdoors to check on some parts and the guy that I spoke to on the phone said, "Are you the guy that posted the video on Facebook about all the rust?"

I told him I was and asked him what his professional opinion was of my mess. He told me that it's probably one of the worst ones he's seen as far as rust goes!

.....

.....I'm just glad that at least I'm number one in something!!!!

I'll keep you guys posted on my progress!

Attachments

“The next day I called Minnesota Outdoors to check on some parts and the guy that I spoke to on the phone said, "Are you the guy that posted the video on Facebook about all the rust?" “

If you spoke with Brad, he‘s seen it all. He’s the Patriarch of anything Bombardier..

Keep up the great work!

Bob

If you spoke with Brad, he‘s seen it all. He’s the Patriarch of anything Bombardier..

Keep up the great work!

Bob

Snowy Rivers

Well-known member

Looking forward to seeing all the nitty gritty details.

One thing's for sure....When you get it all done you will have a great machine....and you will know it INTIMATELY....

There will be no surprises later when you do not need them......"Way out in the sticks in the cold"

One thing's for sure....When you get it all done you will have a great machine....and you will know it INTIMATELY....

There will be no surprises later when you do not need them......"Way out in the sticks in the cold"

Snowy Rivers

Well-known member

Looks great......Well, got the diff in place and the brackets welded on and it's SQUARE!!!!.......I think

Most of the stuff is pretty forgiving as far as square.....The axles, bogies and such don't have to be super tight tolerances...

The alignment of the drive shaft and U joint angle are fairly critical to give smooth operation.

Does the cat have a single piece drive shaft from the tranny to the diffy ???

Just make sure to keep the angles on the joints equal on both ends....Unless there are CV type joints in the shaft.

Try real hard to make sure you do not end up with compound angles on the shaft......Shake rattle and roll will happen if you are not pretty close.

Crankshaft centerline and the diffy centerline need to be parallel.... (Looking from the side) ...then you can set the engine height to get your angle on the shaft.

Also the line from the pinion shaft through the crank looking from the top down needs to be straight too.

Since you are building basically from scratch and not just repairing/cleaning and such.....pay attention to these points and kitty will run smooth

Good luck....fun fun fun.......

Alaska Snow Cat

Member

I would tend to disagree on the above comment especially with the Bombi. Probably because it is such a short machine the Bombi doesn't like to drive very strait unless everything is nice and strait and the axels are set to the correct angle. Each axel is a drop axel has a different angle they are suppose to be at and the rear axels are shorter with a different part number. Worn or bent axels, rims or tires will cause the Bombi to steer poorly. I have found this to be true in even the bigger cats and if you spend any amount of time in one you will want them to steer strait.Most of the stuff is pretty forgiving as far as square.....The axles, bogies and such don't have to be super tight tolerances...

Nice work and best of luck.

Snowy Rivers

Well-known member

I stand corrected.

The Thiokols I have run over the years were very forgiving.

I do agree...the shorter machines can be more fussy......

Like a sightly tighter track on one side will cause the machine to pull to one side.

Maybe I should make my statement a tad more clear.

A tiny error May not cause a big issue....Drive shaft angle error will shake you outta the cab.

AND ruin U JOINTS really quick.....

The Thiokols I have run over the years were very forgiving.

I do agree...the shorter machines can be more fussy......

Like a sightly tighter track on one side will cause the machine to pull to one side.

Maybe I should make my statement a tad more clear.

A tiny error May not cause a big issue....Drive shaft angle error will shake you outta the cab.

AND ruin U JOINTS really quick.....

Ok guys, I finally got some vacation and started working on this thing again. Any one know what kind of and angle the pinion sits on?

I am pretty sure it's an upward angle and the motor is at the same degree going downward chords the pinion so that they are on the same degree angle to prevent massive vibration. I know that I can fudge this a little bit as I'm putting a different motor in it and can adjust it from there.

I just would like to stay close to the original angle if I can. If not, no biggie! Right......

Thanks!!!!

I am pretty sure it's an upward angle and the motor is at the same degree going downward chords the pinion so that they are on the same degree angle to prevent massive vibration. I know that I can fudge this a little bit as I'm putting a different motor in it and can adjust it from there.

I just would like to stay close to the original angle if I can. If not, no biggie! Right......

Thanks!!!!

Attachments

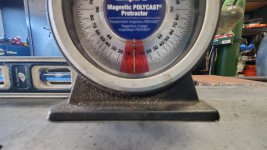

Here's some pictures with an angle indicator attached to it. The first picture is of the bottom of the skid plate. It is almost dead level oh, but it is off 1 degree.

The other picture is of the pinion. It appears that it's two or three degrees in the right direction oh, but I think it probably needs to go a couple more. What do you guys think?

The other picture is of the pinion. It appears that it's two or three degrees in the right direction oh, but I think it probably needs to go a couple more. What do you guys think?

Attachments

western auto

Active member

with a regular driveline pinion angle should mirror trans output angle...... 2up pinion 2deg down transHere's some pictures with an angle indicator attached to it. The first picture is of the bottom of the skid plate. It is almost dead level oh, but it is off 1 degree.

The other picture is of the pinion. It appears that it's two or three degrees in the right direction oh, but I think it probably needs to go a couple more. What do you guys think?

Doing a suspension update. Going to put some different type torsion axles with closed hubs and 4.80 x 12 with 5 on 4.5 lugged wheels.

Got the frame roughed in and narrowed! Narrowed by 3 1/2 inches. Now, just need to spot weld and double check and triple check measurements! Then going to lengthen the frame by approximately 8 inches!

Got the frame roughed in and narrowed! Narrowed by 3 1/2 inches. Now, just need to spot weld and double check and triple check measurements! Then going to lengthen the frame by approximately 8 inches!