Clam shell repair :

. On each end of the clam shell ,on the flat sides ,you will find a 3/4" Allen head plug . Now I do not own a allen wrench to fit one but one can be made from a 5" bolt with a 9/16 head . Just bend it 90 degrees in a vice using a hammer and you now have the tool to remove them . Wait,,, it ain't going to unscrew until you apply some heat . The case is aluminum and the plug is steel and will be really tough to break loose . Use a propane torch to heat the area around the plug and then use your homemade allen wrench tool to loosen it up . It may even take a little cheater bar to help . Ok now that those are removed you will see a 9/16 bolt head in the hole .Using a socket ,remove the bolt . This will allow you to now unbolt the axle housing and get them to release , but only on one side . The clam shell case bolts will now have to be removed to separate the halves and gently lift the double roller chain off the remaining axle that refuses to come out . You can now slip the remaining axle out of the hole . Now you have a double roller chain ,big gear , two Clam shell case halves and two axles .If you look at the end of the axles ,you will see a internal snap ring that when removed will allow access to the oil seals and bushings/bearings . I ran into trouble on the larger one that has the double spocket gear pressed on it . It seemed to wobble when I was getting ready to take it apart . I removed the inner snap ring and lightly tapped the axle on a wooden block to seperate it from the axle tube housing .

The "Wide inner ring ball bearing" fell out in two pieces !! Oh crap ! Where am I going to find one of these ???? I inspected every thing else and all seems to be ok .

I know what caused the problem . The broken bearing is blue from heat and there was no oil in the clam shell when I took it apart . So last night I got on the old computer and started looking .I did not even know what to call the broken part , I was looking for . About midnight I found it ! McMaster- Carr has them in stock . Part # 8090T14 @ $34.76 each

It is a exact match ,right down to the numbers on the old bearing! . I was able to heat up the old "press on" bearing after removing the double roller chain gear with a 3 jaw puller and pull it off . Boy was that thing stuck on there . I am not looking forward to replacing it ! Anyway tomorrow I will order the new bearing that McMaster=Carr says they have "IN Stock " . I will now go ahead and pull down the other side Clam shell and check it again ,just to make sure there are no surprises .

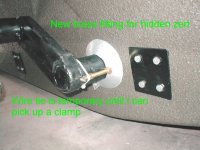

Lesson Learn ??? Make damn sure that Clam Shell has at least 1 pint of gear oil in it at all times before using . There are no drain plugs on the clam shell and you must remove the access plus on the side to add oil . Too much is better than not enough !

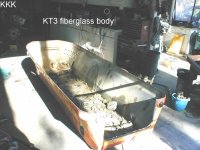

, Well I pushed the wrong button And lost some information on the Kristi KT3 rebuild I been doing for the last couple years . Sooooo ...we are going to rebuild it from day #1 with pictures and part #'s as we go .

, Well I pushed the wrong button And lost some information on the Kristi KT3 rebuild I been doing for the last couple years . Sooooo ...we are going to rebuild it from day #1 with pictures and part #'s as we go .