Thefatsquatch

Active member

Sooooo, I bought another one.

I don't need another big one, but this last year I needed a rescue rig several times for the Thiokol.

And this is what I ended up finding.

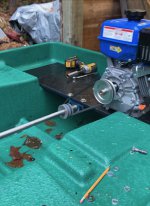

Cushman Trackster.

It appears to have the original motor, so I am coming up with options for replacement engines.

I am thinking a Suzuki intruder motor, because the overdrive would allow for gearing changes based on lower RPMs.

Anyone who has done these know about how much room I have to work with?

I still haven't picked it up, so I don't know much until this weekend.

Also, has anyone built tracks for these?

Like a light belt of conveyer, with bolt on track guides and grousers/track studs?

I was thinking I could make a mold of the track guide and build them out of HDPE, then bolt a small piece of aluminum angle on the outside. Kind of like a few of the Kristi models I have seen.

I don't need another big one, but this last year I needed a rescue rig several times for the Thiokol.

And this is what I ended up finding.

Cushman Trackster.

It appears to have the original motor, so I am coming up with options for replacement engines.

I am thinking a Suzuki intruder motor, because the overdrive would allow for gearing changes based on lower RPMs.

Anyone who has done these know about how much room I have to work with?

I still haven't picked it up, so I don't know much until this weekend.

Also, has anyone built tracks for these?

Like a light belt of conveyer, with bolt on track guides and grousers/track studs?

I was thinking I could make a mold of the track guide and build them out of HDPE, then bolt a small piece of aluminum angle on the outside. Kind of like a few of the Kristi models I have seen.