1970 1202 with a ford 200 motor.

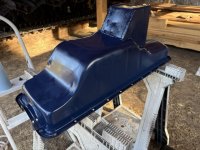

Currently has a deep sump oil pan on the motor. The cat hit something (prior owner) and did some extensive damage to a number of things including the oil pan. When I had the motor out, I pounded the oil pan out and reinstalled it. Problem is that there is a hairline crack and it leaks oil. I can not seem to find a deep sump pan similar to the one that is in the cat. I can not get enough room to weld the crack. If I pull or raise the motor I can do a proper job on welding the crack but would like to look into a replacement pan.

This one looks to be a home job, but who knows.

Any suggestions for locating a replacement pan. Preferably a deep pan so I do not need to replace the pickup as well?

I have tried summit and a regular online search but noting resembles what is in there? What have you all used?

Thanks!

rockaukum

Currently has a deep sump oil pan on the motor. The cat hit something (prior owner) and did some extensive damage to a number of things including the oil pan. When I had the motor out, I pounded the oil pan out and reinstalled it. Problem is that there is a hairline crack and it leaks oil. I can not seem to find a deep sump pan similar to the one that is in the cat. I can not get enough room to weld the crack. If I pull or raise the motor I can do a proper job on welding the crack but would like to look into a replacement pan.

This one looks to be a home job, but who knows.

Any suggestions for locating a replacement pan. Preferably a deep pan so I do not need to replace the pickup as well?

I have tried summit and a regular online search but noting resembles what is in there? What have you all used?

Thanks!

rockaukum