After years of dreaming, this followed me home last week! Somewhere along the way, some modifications were made (440 and 727 Auto Trans swapped into it from the factory 360), and while it's been reasonably well maintained, there's always more to be done. Lots to learn but already excited about the challenge, and excited that I've found such a great forum resource!

-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1977 Tucker 542ASC

- Thread starter tenmile

- Start date

see dreams do come true, congratulations

stay orange and tucker on

stay orange and tucker on

Thanks all! Started with it's 'once over' this weekend with new belts (worn/missing) and new battery. Have some summer projects in mind (clean up some hydraulics, clean up some wiring) but in the meantime, just readying it for it's maiden excursion this week.

On that note, is it possible to rebuild rollers for these? I have a bucket of them in not-so-great-shape and several on the tracks that are missing rear seals. Wanted to see what options I might have to salvage these before trying to source new(er) ones.

On that note, is it possible to rebuild rollers for these? I have a bucket of them in not-so-great-shape and several on the tracks that are missing rear seals. Wanted to see what options I might have to salvage these before trying to source new(er) ones.

I haven't seen anything yet either.Would like to, but haven’t seen details on the 2021 event?

Maiden voyage!

What the photo doesn't say: this is as far as we made it before the motor died. Managed to get it going again but there's some fun that needs to be sorted with the ignition system. Out of curiosity, are EFI swaps popular with this crowd? While an engine swap of some sort would be fun, it wouldn't have the torque of the 440 so thinking of doing a TBI swap (either homemade or a Holley or Edelbrock kit).

What the photo doesn't say: this is as far as we made it before the motor died. Managed to get it going again but there's some fun that needs to be sorted with the ignition system. Out of curiosity, are EFI swaps popular with this crowd? While an engine swap of some sort would be fun, it wouldn't have the torque of the 440 so thinking of doing a TBI swap (either homemade or a Holley or Edelbrock kit).

Attachments

PJL

Well-known member

I had the AFI system installed on the 1200 with the 300 CID Ford 6.

They make 2 for the 440.

affordable-fuel-injection.com

affordable-fuel-injection.com

affordable-fuel-injection.com

affordable-fuel-injection.com

Holley also has a kit.

www.holley.com

www.holley.com

The EFI system eliminated the hot vapor locking. Starts right up hot or cold. Good throttle response and driveability. Power seemed about the same but the fuel economy improved by about a gallon per hour. The AFI system includes a new distributor and ignition components. Its been in about 3 years now and not a bit of trouble.

www.hotrod.com

www.hotrod.com

There have been a few other EFI swaps here.

They make 2 for the 440.

MOPAR / CHRYSLER Legacy Complete TBI Kit – Affordable Fuel Injection

affordable-fuel-injection.com

affordable-fuel-injection.com

Chrysler/Mopar Optimum series TBI kit – Affordable Fuel Injection

affordable-fuel-injection.com

affordable-fuel-injection.com

Holley also has a kit.

Fuel Injection Kits & EFI Systems | Holley Performance Products

THE New Standard in Fuel Injection! Street to Race - From GM's factory COPO Camaro to NASCAR to your car!

The EFI system eliminated the hot vapor locking. Starts right up hot or cold. Good throttle response and driveability. Power seemed about the same but the fuel economy improved by about a gallon per hour. The AFI system includes a new distributor and ignition components. Its been in about 3 years now and not a bit of trouble.

Holley Sniper EFI install and dyno test on a 440

Dyno testing a Holley Sniper EFI kit on a 440. Does it work as advertised?

There have been a few other EFI swaps here.

Last edited:

That's good to know an EFI swap won't make me persona non grata around these parts! I hadn't seen the AFI kits before, and had my eyes on the Holley Sniper system as I understand the MAP sensor is integrated so I wouldn't need to figure out a new intake to then have to run the MAF/MAP sensor like some of the other kits (Factory air cleaner is a two port system), but willing to consider all options. I just want something that will ensure I don't get stranded out in the woods with a finicky carb due to elevation changes, etc.

That's good to know an EFI swap won't make me persona non grata around these parts! I hadn't seen the AFI kits before, and had my eyes on the Holley Sniper system as I understand the MAP sensor is integrated so I wouldn't need to figure out a new intake to then have to run the MAF/MAP sensor like some of the other kits (Factory air cleaner is a two port system), but willing to consider all options. I just want something that will ensure I don't get stranded out in the woods with a finicky carb due to elevation changes, etc.

I was considering installing a Holley Sniper system on our 1544 project Tucker but decided against it. A very good friend of mine has a Ford Bronco project and he had a fair amount of email correspondence with a company called EFISystemPro.com. They seem to have a lot of experience with the Holley Sniper system, and my friend mentioned reliability as one of the things he was looking for. This is quoted from one of the emails he received:

About the second time that someone uses the word reliable in a conversation regarding the Sniper I start to turn the conversation toward a Terminator EFI System. These are significantly more expensive but if it's me on the US/Canada boarder, 50 miles up a trail like that and 100 miles from a garage then that's what I'm going with.

https://www.efisystempro.com/terminator/terminator-universal-4BBl-tbi-systems-550-405-406-407-408

In general these are similar to the Sniper EFI System in that they both are throttle-body based injection systems but the similarity ends there. While the Sniper ECU is in the throttle body the Terminator throttle body is in a potted, sealed, aluminum case that is durable enough to be installed in the engine compartment but most folks install inside the vehicle. The injectors are fully accessible and use a normal locking connector, not hidden behind a faux end tank and prone to popping off. No built-in regulator is included with the Terminator which means you'll be running a quality stand-along regulator.

Give this some thought. Holley recently released their Terminator X Stelath TBI system but it sort of lands between the two when it comes to a price/quality perspective. I'm quite happy with my Sniper for my 4-mile one way trip to work and back. But I'm going with the Terminator for something like this.

Super helpful insight, thanks Blackfoot! I wouldn't have thought as $1K as a 'low end kit' but I guess for Holley, that's enough to cut some corners. The Terminator X Stealth seems like a nice compromise between the two. I'm going to try to re-vamp the wiring and eliminate any concerns on the ignition side to see how it runs before I commit to the EFI.

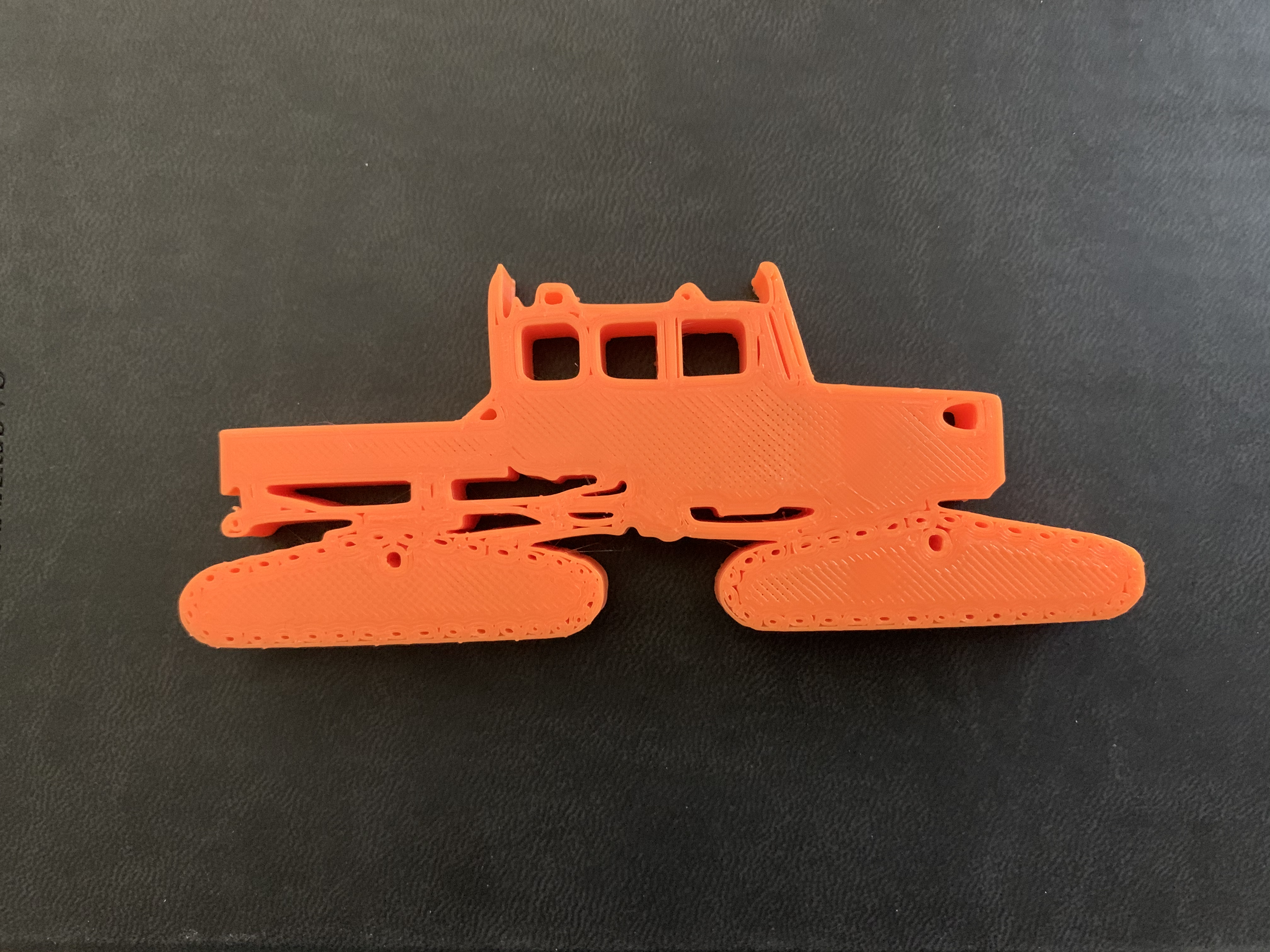

No time to dig into it this week unfortunately, but did find some time to use my Xmas present (3D printer) to print a model of a Tucker, complete in orange!

No time to dig into it this week unfortunately, but did find some time to use my Xmas present (3D printer) to print a model of a Tucker, complete in orange!

keychain size ? PriceSuper helpful insight, thanks Blackfoot! I wouldn't have thought as $1K as a 'low end kit' but I guess for Holley, that's enough to cut some corners. The Terminator X Stealth seems like a nice compromise between the two. I'm going to try to re-vamp the wiring and eliminate any concerns on the ignition side to see how it runs before I commit to the EFI.

No time to dig into it this week unfortunately, but did find some time to use my Xmas present (3D printer) to print a model of a Tucker, complete in orange!

View attachment 133689

I can probably make one for ya, I’ll send you a PM.keychain size ? Price

olympicorange

Active member

if its nuts & bolts, there will always be something. no matter how far ahead you look. dig the rear seats, another rear rider to the gang.Maiden voyage!

What the photo doesn't say: this is as far as we made it before the motor died. Managed to get it going again but there's some fun that needs to be sorted with the ignition system. Out of curiosity, are EFI swaps popular with this crowd? While an engine swap of some sort would be fun, it wouldn't have the torque of the 440 so thinking of doing a TBI swap (either homemade or a Holley or Edelbrock kit).

Tenmile,

I typically write my forum posts as on email on my computer, then I proofread it, and maybe revise it, before posting. In theory anyway, this makes for a better post. When I revised the post last time I deleted a lot of information.

I realize you’re new to the forum, so you aren’t familiar with the project Tuckers my snowcat buddy, Scott, and I have worked on. My “keeper machine" is called Thundercat. It’s a 1980 Tucker 1644 and has an 8.1 Liter Chevy Vortec engine coupled to an Allison AT545 transmission. This machine is basically the poster child for project creep, and has taken an absurd amount of time and effort. But it’s been fun….

Here’s a link to a video of our first day of testing it:

This is probably my favorite of the videos:

Our other big project is called Snowzilla, and it’s being built for forum member WBuffetJr1, or WBJ1 as I refer to him. That machine is a 1980 Tucker 1643 powered by a 6.2 Liter GM L94 engine, basically an all aluminum LS series engine, and it’s also mated to an Allison AT545 transmission.

The 1544 was acquired in a package deal with a trailer. I wasn’t in the market for another Tucker, but the deal was simply too good to pass up, so I bought it. It’s a 1986, has the optional 360 CID engine, a factory installed Allison AT545 and a front winch. The plan all along has been to keep the trailer and eventually sell the Tucker, after we have everything working to our satisfaction, and have it in “no excuses” condition. We’ll ask a fair price for it, but that said, we have to keep an eye on the financial considerations of any modifications. “Is a customer willing to pay for such and such? If the answer is no, then it’s not worth it. I am a huge believer in the merits of the GM LS series engines. But installing one PROPERLY in a Tucker is a lot of work and the parts required add up pretty fast. My off-the-cuff estimate is about $4K in parts, in addition to the cost of the engine, and that doesn’t include a transmission, or a nickel for our labor.

I’ve been messing around with Tuckers for roughly 12 years and the prices of used machines have risen substantially. If you buy a machine at the right price you can afford to put money into it and still come out okay. But at today’s prices it’s tough. I don’t see many potential customers being willing to spend an extra $10K for an LS engine in a Tucker. That number might evoke “Holy Cr*P, that’s absurd", but having been involved in two LS conversions, it’s actually not enough compensation for all the labor and headaches involved.

The Sniper system is about $1K for the basic kit, but there’s more parts to buy. The master kit is just over $1,300, and if you want to control ignition timing, that adds roughly another $500. We talked about installing a Sniper system on the 1544’s Chrysler 360 Industrial and ran the numbers. We thought we would need to get almost $2,500 to cover all the parts and the labor to make it worth it for us. That was for a complete system including the Hyperspark ignition system. But if you read the test results, you get better starting and drivability, but a Sniper system doesn’t add any power to the engine, and there’s the issue of dependability/reliability. The Terminator system starts at $2,700, and there’s no capability to control ignition timing on a Chrysler LA series engine. For me, given the choices I’d rather spent the extra money for an LS engine and get a truly fantastic engine with some serious power gains. But we have to think of what a customer is willing to pay for, not what we might want...

I typically write my forum posts as on email on my computer, then I proofread it, and maybe revise it, before posting. In theory anyway, this makes for a better post. When I revised the post last time I deleted a lot of information.

I realize you’re new to the forum, so you aren’t familiar with the project Tuckers my snowcat buddy, Scott, and I have worked on. My “keeper machine" is called Thundercat. It’s a 1980 Tucker 1644 and has an 8.1 Liter Chevy Vortec engine coupled to an Allison AT545 transmission. This machine is basically the poster child for project creep, and has taken an absurd amount of time and effort. But it’s been fun….

Here’s a link to a video of our first day of testing it:

This is probably my favorite of the videos:

Our other big project is called Snowzilla, and it’s being built for forum member WBuffetJr1, or WBJ1 as I refer to him. That machine is a 1980 Tucker 1643 powered by a 6.2 Liter GM L94 engine, basically an all aluminum LS series engine, and it’s also mated to an Allison AT545 transmission.

The 1544 was acquired in a package deal with a trailer. I wasn’t in the market for another Tucker, but the deal was simply too good to pass up, so I bought it. It’s a 1986, has the optional 360 CID engine, a factory installed Allison AT545 and a front winch. The plan all along has been to keep the trailer and eventually sell the Tucker, after we have everything working to our satisfaction, and have it in “no excuses” condition. We’ll ask a fair price for it, but that said, we have to keep an eye on the financial considerations of any modifications. “Is a customer willing to pay for such and such? If the answer is no, then it’s not worth it. I am a huge believer in the merits of the GM LS series engines. But installing one PROPERLY in a Tucker is a lot of work and the parts required add up pretty fast. My off-the-cuff estimate is about $4K in parts, in addition to the cost of the engine, and that doesn’t include a transmission, or a nickel for our labor.

I’ve been messing around with Tuckers for roughly 12 years and the prices of used machines have risen substantially. If you buy a machine at the right price you can afford to put money into it and still come out okay. But at today’s prices it’s tough. I don’t see many potential customers being willing to spend an extra $10K for an LS engine in a Tucker. That number might evoke “Holy Cr*P, that’s absurd", but having been involved in two LS conversions, it’s actually not enough compensation for all the labor and headaches involved.

The Sniper system is about $1K for the basic kit, but there’s more parts to buy. The master kit is just over $1,300, and if you want to control ignition timing, that adds roughly another $500. We talked about installing a Sniper system on the 1544’s Chrysler 360 Industrial and ran the numbers. We thought we would need to get almost $2,500 to cover all the parts and the labor to make it worth it for us. That was for a complete system including the Hyperspark ignition system. But if you read the test results, you get better starting and drivability, but a Sniper system doesn’t add any power to the engine, and there’s the issue of dependability/reliability. The Terminator system starts at $2,700, and there’s no capability to control ignition timing on a Chrysler LA series engine. For me, given the choices I’d rather spent the extra money for an LS engine and get a truly fantastic engine with some serious power gains. But we have to think of what a customer is willing to pay for, not what we might want...

Don't you know it with 'always be something'if its nuts & bolts, there will always be something. no matter how far ahead you look. dig the rear seats, another rear rider to the gang.

Tenmile,

I typically write my forum posts as on email on my computer, then I proofread it, and maybe revise it, before posting. In theory anyway, this makes for a better post. When I revised the post last time I deleted a lot of information.

I realize you’re new to the forum, so you aren’t familiar with the project Tuckers my snowcat buddy, Scott, and I have worked on. My “keeper machine" is called Thundercat. It’s a 1980 Tucker 1644 and has an 8.1 Liter Chevy Vortec engine coupled to an Allison AT545 transmission. This machine is basically the poster child for project creep, and has taken an absurd amount of time and effort. But it’s been fun….

Here’s a link to a video of our first day of testing it:

This is probably my favorite of the videos:

Our other big project is called Snowzilla, and it’s being built for forum member WBuffetJr1, or WBJ1 as I refer to him. That machine is a 1980 Tucker 1643 powered by a 6.2 Liter GM L94 engine, basically an all aluminum LS series engine, and it’s also mated to an Allison AT545 transmission.

The 1544 was acquired in a package deal with a trailer. I wasn’t in the market for another Tucker, but the deal was simply too good to pass up, so I bought it. It’s a 1986, has the optional 360 CID engine, a factory installed Allison AT545 and a front winch. The plan all along has been to keep the trailer and eventually sell the Tucker, after we have everything working to our satisfaction, and have it in “no excuses” condition. We’ll ask a fair price for it, but that said, we have to keep an eye on the financial considerations of any modifications. “Is a customer willing to pay for such and such? If the answer is no, then it’s not worth it. I am a huge believer in the merits of the GM LS series engines. But installing one PROPERLY in a Tucker is a lot of work and the parts required add up pretty fast. My off-the-cuff estimate is about $4K in parts, in addition to the cost of the engine, and that doesn’t include a transmission, or a nickel for our labor.

I’ve been messing around with Tuckers for roughly 12 years and the prices of used machines have risen substantially. If you buy a machine at the right price you can afford to put money into it and still come out okay. But at today’s prices it’s tough. I don’t see many potential customers being willing to spend an extra $10K for an LS engine in a Tucker. That number might evoke “Holy Cr*P, that’s absurd", but having been involved in two LS conversions, it’s actually not enough compensation for all the labor and headaches involved.

The Sniper system is about $1K for the basic kit, but there’s more parts to buy. The master kit is just over $1,300, and if you want to control ignition timing, that adds roughly another $500. We talked about installing a Sniper system on the 1544’s Chrysler 360 Industrial and ran the numbers. We thought we would need to get almost $2,500 to cover all the parts and the labor to make it worth it for us. That was for a complete system including the Hyperspark ignition system. But if you read the test results, you get better starting and drivability, but a Sniper system doesn’t add any power to the engine, and there’s the issue of dependability/reliability. The Terminator system starts at $2,700, and there’s no capability to control ignition timing on a Chrysler LA series engine. For me, given the choices I’d rather spent the extra money for an LS engine and get a truly fantastic engine with some serious power gains. But we have to think of what a customer is willing to pay for, not what we might want...

Thanks for the reply- I actually read through some of your build posts when I googled "LS Swap Tucker" and got a kick out of your comments about the YouTube 'Influencer' swap. Lots of cut corners and while I appreciate the 5.3, I don't think it'd be the motor I would swap into a Tucker. I'm (fortunately or unfortunately depending on the project) no stranger to LS swaps- I'm daily driving an LC9 swapped Grand Wagoneer, and have previously swapped an LS3 into a '65 Chevelle, LS1 into a '65 Deville and a L35 into a CJ7. I think your L94 swap is an excellent choice, other alternatives I was debating was an LQ4 or LQ9, but want to give the ol' girl her fair chance first. BTW: Are you in the mountain west somewhere? I seem to recall a reference to UT or CO.

For now, back to the challenges at hand! Got it home and started diving into the ignition system. Felt like I was chasing a ghost for a while but eventually realized 43 year old wiring combined with a semi failing distributor (rotor separated from the shaft and had 90 degrees of free play!) was causing a plethora of intermittent problems. Checked compression (surprisingly good for a motor this old)/plugs/wires, new distributor, re-set the timing, rewired everything downstream of the keyed switch on the ignition system (with the exception of the electric choke on the 4bbl) and as of this morning, she fires up and runs great! That's triggered the identification of a new problem of the charging system not working correctly (old wiring, questionable modifications, etc.), which means I'll be re-wiring all of that next week when some parts I ordered come in. Also need to re-work the fuel lines, there's an electric fuel pump pumping into the mechanical with some old fuel lines there; I'm contemplating bypassing the mechanical entirely and just using the electric but haven't made a final decision yet.

Looking forward to the next problem to solve: I'm going to remove the old rear hydraulic control valve (leaking, with old lines) and have some new hydraulic lines made for the rest of the system. I started looking at the pump, and realized it doesn't align with the Vickers V20P pump that's been referenced here on the forum. I don't have a picture handy, but mine has 4 ports on it (1x on the center bottom back, 2x on the upper back, 1x on the top front near the pulley) I was going to remove the output/input from the rear hydraulic control box but wasn't sure if I could just plug the ports on the pump or if I need to build a bypass hose. Anyone know what pump this might be?

TM,

An LS series powered Grand Wagoneer sounds like a heck of a nice ride. Good on you for that combination!

I have no clue what your hydraulic pump might be, if it's not a V-20P. A suggestion I make to anyone who buys a used Tucker is to call the factory, (866) SNO CAT1, with your serial number and ask for the original order sheet. This will tell you exactly how the machine was configured when it left the factory, and helps when trying to buy replacement parts. I have found Tucker to be very helpful in providing the order sheet.

All of the Tuckers I've bought have had both electric and mechanical fuel pumps. The electric pumps have been controlled by a switch on the instrument panel. I've always thought of it as an auxiliary pump used when the machine is in more extreme angles to help out the mechanical pump.

I can sympathize on your wiring issues. It seems by the time these machines get to us as "recreational users" they have had several owners whose mechanical aptitude with regard to wiring is, shall I say, "limited". All kinds of "creativity" that's more correctly called buffoonery. It's never fun to sort that out and get it squared away.

Yes, I live in Northern Utah.

An LS series powered Grand Wagoneer sounds like a heck of a nice ride. Good on you for that combination!

I have no clue what your hydraulic pump might be, if it's not a V-20P. A suggestion I make to anyone who buys a used Tucker is to call the factory, (866) SNO CAT1, with your serial number and ask for the original order sheet. This will tell you exactly how the machine was configured when it left the factory, and helps when trying to buy replacement parts. I have found Tucker to be very helpful in providing the order sheet.

All of the Tuckers I've bought have had both electric and mechanical fuel pumps. The electric pumps have been controlled by a switch on the instrument panel. I've always thought of it as an auxiliary pump used when the machine is in more extreme angles to help out the mechanical pump.

I can sympathize on your wiring issues. It seems by the time these machines get to us as "recreational users" they have had several owners whose mechanical aptitude with regard to wiring is, shall I say, "limited". All kinds of "creativity" that's more correctly called buffoonery. It's never fun to sort that out and get it squared away.

Yes, I live in Northern Utah.

Thanks! Still needs a little bit of dialing in but between the LS and some suspension upgrades, it's a fun ride to tool around in. Always gets a lot of attention and I have yet to meet someone who doesn't have a Grand Wagoneer story.

On your advice, Dan at SnoCat was super helpful in getting me the build sheet. It also lists a V20P, but it must be some different variant given the number of ports I have. I'm going to try to see if I can identify a tag on it under the years of grease and dirt to help me identify ports, etc. Also interesting to note it was a 360ci/5spd as delivered, and is now a 440/727 so could be questionable it's actually a V20P still.

My wiring project is halfway complete inbetween other duties and bad weather, but hoping to complete by end of weekend so I can move on to other items to be refreshed!

On your advice, Dan at SnoCat was super helpful in getting me the build sheet. It also lists a V20P, but it must be some different variant given the number of ports I have. I'm going to try to see if I can identify a tag on it under the years of grease and dirt to help me identify ports, etc. Also interesting to note it was a 360ci/5spd as delivered, and is now a 440/727 so could be questionable it's actually a V20P still.

My wiring project is halfway complete inbetween other duties and bad weather, but hoping to complete by end of weekend so I can move on to other items to be refreshed!

New distributor: ✅

New wiring for all ignition to coil, electronic ignition controller, new ballast, etc: ✅

New grounding cables to firewall and block: ✅

New Alternator wiring (to battery, and to voltage regulator): ✅

New fused power lead to main power distrobution block: ✅

New voltage regulator: ✅

New ignition switch, water temp gauge, voltmeter: ✅

Replaced Thermostat, Heater Hoses, New Coolant Reservoir: ✅

Replaced some really questionable soft fuel lines: ✅

Fixed Horn switch & replaced horns: ✅

Replaced hood edge protector: ✅

Oil Change: ✅

Discovered I need a new oil filler cap and radiator cap, so need to grab both of those. I'm sure I'm missing a half dozen other little things I did as well. But, she fired right up the other morning after cold soaking in 7 degree weather which makes me super happy!

Now on to hydraulics (remove rear PTO box, new lines to orbital valve and hydraulic steering ram) and replacing several rollers that are broken/missing seals before the Sno-Cat jamboree in March!

New wiring for all ignition to coil, electronic ignition controller, new ballast, etc: ✅

New grounding cables to firewall and block: ✅

New Alternator wiring (to battery, and to voltage regulator): ✅

New fused power lead to main power distrobution block: ✅

New voltage regulator: ✅

New ignition switch, water temp gauge, voltmeter: ✅

Replaced Thermostat, Heater Hoses, New Coolant Reservoir: ✅

Replaced some really questionable soft fuel lines: ✅

Fixed Horn switch & replaced horns: ✅

Replaced hood edge protector: ✅

Oil Change: ✅

Discovered I need a new oil filler cap and radiator cap, so need to grab both of those. I'm sure I'm missing a half dozen other little things I did as well. But, she fired right up the other morning after cold soaking in 7 degree weather which makes me super happy!

Now on to hydraulics (remove rear PTO box, new lines to orbital valve and hydraulic steering ram) and replacing several rollers that are broken/missing seals before the Sno-Cat jamboree in March!

Dumb question: are the pin roller bushings something special, or just some standard steel spacers like this?

I have several that are worn out or missing, and since I'm pulling the tracks off to replace rollers seems like a great time to take care of that as well.

Hillman 1/2 I.D x 5/8 O.D x 1-1/2 in. Seamless Steel Spacer (5-Pack) 880421 - The Home Depot

Spacers are fasteners that are used to create space between two objects, often to properly position them. In the world of electronic components and electronic hardware, spacers are typically used to space

www.homedepot.com

I have several that are worn out or missing, and since I'm pulling the tracks off to replace rollers seems like a great time to take care of that as well.

they are special, they are hardened, Rockwell 44, most use whatever works and is the cheapest, basically why waste the money...

The Rockwell 44 hardened versions make sense, though where does one even find these versions? Tucker? They didn't mention them as being available when I asked what they did have around for these old metal tracks.

Keeping with the 'whatever works' theme- what DOES work size wise and where have people been buying them? I can't imagine what I found at Home Depot is exactly the best fit in both of those categories

Keeping with the 'whatever works' theme- what DOES work size wise and where have people been buying them? I can't imagine what I found at Home Depot is exactly the best fit in both of those categories

a good machine shop can help out with the size and shape of the sprockets rollers, then you can have them hardened, sadly tucker inc has a very little number of parts available for the pontoon machine,,,

the real problem is, there were very few machine ever built (1250 through the mid seventies, that is little over 30 years of manufacturing) and almost to a machine, were used well beyond their life cycle and for the most part have about 50 hours of life left in them and many many many have only 5 hours of use left in them, the real rub comes from the true cost of having new parts made and or finding the last stash of parts, the challenge is balancing between the cost and the very few times a year you use it, and praying it does break a mile from the nearest road

good luck, wish I could offer you more help.

the real problem is, there were very few machine ever built (1250 through the mid seventies, that is little over 30 years of manufacturing) and almost to a machine, were used well beyond their life cycle and for the most part have about 50 hours of life left in them and many many many have only 5 hours of use left in them, the real rub comes from the true cost of having new parts made and or finding the last stash of parts, the challenge is balancing between the cost and the very few times a year you use it, and praying it does break a mile from the nearest road

good luck, wish I could offer you more help.

Thanks for the reply and guidance as always

I pulled a roller off and, if it helps anyone else with a 500 series machine, the roller is .50" ID, ~.10" Wall thickness, .70" (I measured .72" but could be some rust or pitting) OD, and 1" in height. I found some that I think will work on Amazon, Grainger didn't have anything and a few other sites had things that would work but were a bit too short. I'll buy a package of these ones in question and let people know how they work out!

I pulled a roller off and, if it helps anyone else with a 500 series machine, the roller is .50" ID, ~.10" Wall thickness, .70" (I measured .72" but could be some rust or pitting) OD, and 1" in height. I found some that I think will work on Amazon, Grainger didn't have anything and a few other sites had things that would work but were a bit too short. I'll buy a package of these ones in question and let people know how they work out!

If they work out would you mind posting where you obtained them?Thanks for the reply and guidance as always

I pulled a roller off and, if it helps anyone else with a 500 series machine, the roller is .50" ID, ~.10" Wall thickness, .70" (I measured .72" but could be some rust or pitting) OD, and 1" in height. I found some that I think will work on Amazon, Grainger didn't have anything and a few other sites had things that would work but were a bit too short. I'll buy a package of these ones in question and let people know how they work out!

You might try McMaster-Carr for the spacers. They have all kinds of hardware. Look them up online . Anyone can order , not just a distributor. I think they are based out of Chicago, but have other warehouses. Buying from them works well for us, they are an hour behind by time zone, so I can order late and still have it sent out today.

Final stretch trying to get her ready for Snowcat Jamboree this weekend! Replaced 25 rollers, and several bushings on the pins, though I have more to do on that front as well as grease the remaining rollers. I made the mistake of removing the track off a pontoon to do the first set of rollers and then spent several hours trying to muscle it back into place alone as I didn't have help. That, was exhausting. I did the rest of the rollers while the tracks were still on the pontoons. That kept me from being able to assess the state of the pontoons and other wear items but at this point, that will need to wait for summer.

A couple of comments:

-@GMoose- these are the bushings I bought. They are not quite as thick as the factory ones, but are right diameter ID and length wise. https://www.amazon.com/gp/product/B00NQR0TVE

-@230 Pilot- I looked at McMaster-Carr and they had the right ID/OD but too long for length, and their cost for custom bushings were eye watering. Figured I'd give these cheaper ones from Amazon a try and see how they hold up. My bigger challenge is some of my pins had NO bushings, so even cheap/crappy ones are > none.

-Interesting observation: the new rollers from Tucker are very, very different then what I have on mine which I think are the original style. First of all: they're sealed bearings. No grease hole or fitting. Secondly, they're larger than the old ones by a good 1/4-1/2" in diameter. I haven't measured specifically but I was really surprised at how much bigger they are. I have a couple of spots on my track where they bind on one pontoon and I hope that doesn't create a bigger problem down the line.

Question:

-How tight is 'too tight' for track tension? I was always told at it's loosest point, I shouldn't be able to lift the roller more than 1/2" off the track. Does that sound right? What if it's tight enough that 1/4" is as most loose as I can get it?

A couple of comments:

-@GMoose- these are the bushings I bought. They are not quite as thick as the factory ones, but are right diameter ID and length wise. https://www.amazon.com/gp/product/B00NQR0TVE

-@230 Pilot- I looked at McMaster-Carr and they had the right ID/OD but too long for length, and their cost for custom bushings were eye watering. Figured I'd give these cheaper ones from Amazon a try and see how they hold up. My bigger challenge is some of my pins had NO bushings, so even cheap/crappy ones are > none.

-Interesting observation: the new rollers from Tucker are very, very different then what I have on mine which I think are the original style. First of all: they're sealed bearings. No grease hole or fitting. Secondly, they're larger than the old ones by a good 1/4-1/2" in diameter. I haven't measured specifically but I was really surprised at how much bigger they are. I have a couple of spots on my track where they bind on one pontoon and I hope that doesn't create a bigger problem down the line.

Question:

-How tight is 'too tight' for track tension? I was always told at it's loosest point, I shouldn't be able to lift the roller more than 1/2" off the track. Does that sound right? What if it's tight enough that 1/4" is as most loose as I can get it?

Can you post some pics of the Tucker roller solution and price point?