-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1973 Tucker Sno Cat 1443 New to Me

- Thread starter Track Addict

- Start date

Very pleased with the final product. Front will be getting the same treatment eventually.

Paint in progress and loving the paint tent! Passenger carrier stripped ready for degrease then weld touch up. The last three matching idlers stripped.

These six steel idlers must have been from the Tucker Harley/AMF years of cutting cost period before the return to Tucker OE cast aluminum glory? Big weight difference.

Going to need a vacation after this project.

Degreased the passenger carrier. Did lots of welding on this one. These will come off again in the future for some more improvements.

Welded in the new additional grease zerk bings.

Housing painted ready to hang.

Bearings fit to shafts.

Degreased the passenger carrier. Did lots of welding on this one. These will come off again in the future for some more improvements.

Welded in the new additional grease zerk bings.

Housing painted ready to hang.

Bearings fit to shafts.

Idlers in process.

Diff filled, carriers greased, idlers greased. Sprockets, sliders, and step back on.

Few lines of track for breakfast then North to the testing grounds ahead of some SNO worn the kids!

Better than new 1973. Front tracks are now jelly

New England is odd in many ways…

On the road again. I just can't wait to get on the road again. The life I love is going to SV to SnoCat with my friends.

Bluebird day, warm with over 2’ of powder which is rare for the North East. Sno was too deep to get up to the T Bar summit. Didn't want to beat on the cat digging up so we were satisfied with the 3/4 trip with MT-Washington and Pleasant Mountain views.

Plan was to track out the trails so the kids could ride their snowmobiles.

We had reverse down a ways slowly and enjoyed the smiles as the back country skiers were ripping by enjoying the fruits of Burnt Meadow MTN!

Plan was to track out the trails so the kids could ride their snowmobiles.

We had reverse down a ways slowly and enjoyed the smiles as the back country skiers were ripping by enjoying the fruits of Burnt Meadow MTN!

Most of the way down I was tracking a turn around for the sleds and then bang! WTF was that. Jr and I hoped out. On his side he says their is a crack in the tube.

Turns out new tie rod was a rookie engineering disaster. I but welded the shortened tubes and that failed. Sorry Davenet yours are tainted as well

The two boys hiked down to get a snowmobile. I had the tools to get to work and remove the tie rod. Plan was to take down and weld it. Luckily some club members were at the lodge ready to assist.

Had nice a nice office as I waited for transport and a few more tools.

Turns out new tie rod was a rookie engineering disaster. I but welded the shortened tubes and that failed. Sorry Davenet yours are tainted as well

The two boys hiked down to get a snowmobile. I had the tools to get to work and remove the tie rod. Plan was to take down and weld it. Luckily some club members were at the lodge ready to assist.

Had nice a nice office as I waited for transport and a few more tools.

This time we did what I should have done and inserted a steel rod then welded for strength.

So in short order we are back up ready to install the tie rod and go about fun. The tables were out of sink and in deep sno. Tried using the snowmobile and an anchor to winch the front table into alignment. Fail

Send jr down to the bottom to fetch all the tie down traps to hook to a tree. I had to back up to straighten. Started working until I heard “Dad, another piece fell out from under the Tucker”. WTF FML

Hop out and the front drive shaft is on the ground. The full turn prob over extended turn was too much and broke a strap.

Now we had a rear track drive car in the powder. Jr leaned some new language as I assessed. Few maneuvers with him spotting the tie rod and we were back aligned and hooked up.

Last turn of my custom table bolt wrench and it broke.

Send jr down to the bottom to fetch all the tie down traps to hook to a tree. I had to back up to straighten. Started working until I heard “Dad, another piece fell out from under the Tucker”. WTF FML

Hop out and the front drive shaft is on the ground. The full turn prob over extended turn was too much and broke a strap.

Now we had a rear track drive car in the powder. Jr leaned some new language as I assessed. Few maneuvers with him spotting the tie rod and we were back aligned and hooked up.

Last turn of my custom table bolt wrench and it broke.

Now the cat didn’t want to go up hill and a 3 point turn was not a great idea. The back tie rod is also flawed so I have that in the back of my mind.

Decide to reverse down the 1/2 mile. Thinking was the table trailing the front trunion pivot would keep the non powered front end from hunting which worked well

Got into some drifts toward the bottom and the front tracks started dragging stopping the production. Few maneuvers and we were down.

Loaded on the trailer and headed back to the shop to assess. Boys were on powder overdose and maybe a little spf in J Tucker would have been wise?

Decide to reverse down the 1/2 mile. Thinking was the table trailing the front trunion pivot would keep the non powered front end from hunting which worked well

Got into some drifts toward the bottom and the front tracks started dragging stopping the production. Few maneuvers and we were down.

Loaded on the trailer and headed back to the shop to assess. Boys were on powder overdose and maybe a little spf in J Tucker would have been wise?

So great learning lesson. Two S55 u joints and a strap kit on the way.

Got the broke bolts out, cleaned up the tie rod work and laid some paint.

Before I pulled the rod in recentered the table and pivot. All good here.

Got the broke bolts out, cleaned up the tie rod work and laid some paint.

Before I pulled the rod in recentered the table and pivot. All good here.

Wow. With that kind of luck, you'd think it was painted green.

It’s exactly 1” and just so happened to have that in my friends shop. Took a second piece home to fix the rear.

Order right from McMaster for yours. I’ll fix if you want to take off.

Order right from McMaster for yours. I’ll fix if you want to take off.

New u-joints, hardware, driveshaft timed and installed.

Front tie rod and table aligned. Added a rear clamp to allow tube pivot but tension for wear. I like to lock down the table side tie rod ends and keep the pivot looser for easy service and visability.

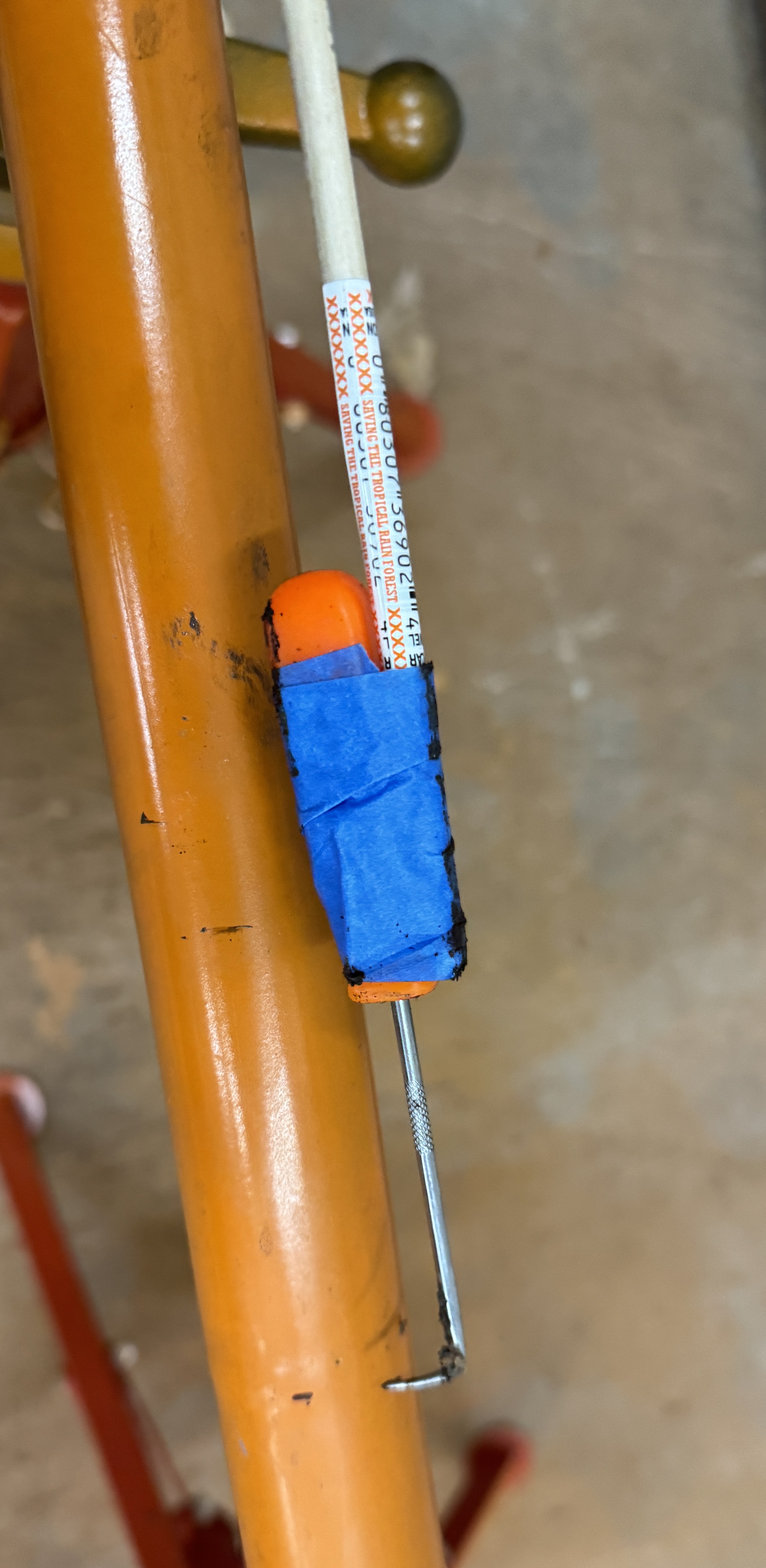

Rear tie rod off. I could kind of see where I welded but used a pic and dowel to confirm. Managed to cut right on my weld.

Rod inserted, welded, ground, and paint.

Front tie rod and table aligned. Added a rear clamp to allow tube pivot but tension for wear. I like to lock down the table side tie rod ends and keep the pivot looser for easy service and visability.

Rear tie rod off. I could kind of see where I welded but used a pic and dowel to confirm. Managed to cut right on my weld.

Rod inserted, welded, ground, and paint.

Adjusted the track tension on all four tracks. Adjusted all the idler wheels nuts now that they have some run in.

Installed the improved tie rod and aligned the rear table. Few test laps and turns in the shop it seems happy

Thanks to Davenet for the decal. Tucker has had weird energy since it came off and happy to identify as Chrysler again.

Installed the improved tie rod and aligned the rear table. Few test laps and turns in the shop it seems happy

Thanks to Davenet for the decal. Tucker has had weird energy since it came off and happy to identify as Chrysler again.

Load it, send it, Sun Valley 2024!

Tucker has had weird energy since it came off and happy to identify as Chrysler again.

Now that you mention that, everything did start going sideways on that thing after that decal came off . . .

Hopefully the hex is removed!

Adjusted brakes, axle nut tension, greased bearings, and aired tires.

Heard Sun Valley is classy so vacuumed the cab.

Heard Sun Valley is classy so vacuumed the cab.

Great trip to Idaho! Tucker and the little /6 did well with the big power western cats.

East Coast Preserve headed home a little heavier…

East Coast Preserve headed home a little heavier…

Cat and trailer unloaded and cleaned up. Replaced the backer bolt and made some custom spacers for the Fun-raising Trailer.

Getting the shop into summer formation.

Getting the shop into summer formation.