Boy it can be a lot of work to get pictures on this website!!! sorry no more big pics they wont post...

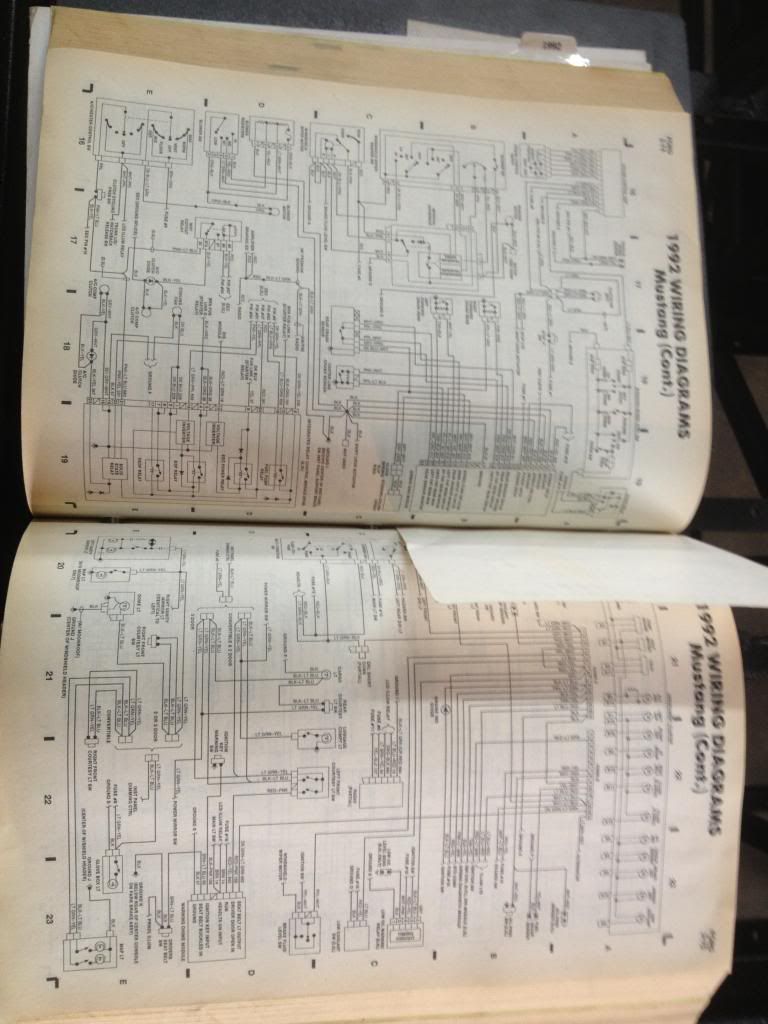

Got the end complete the harness comes out in two place because one will go to the rack of relays under the drivers seat and the other will go to the engine harness and dash..

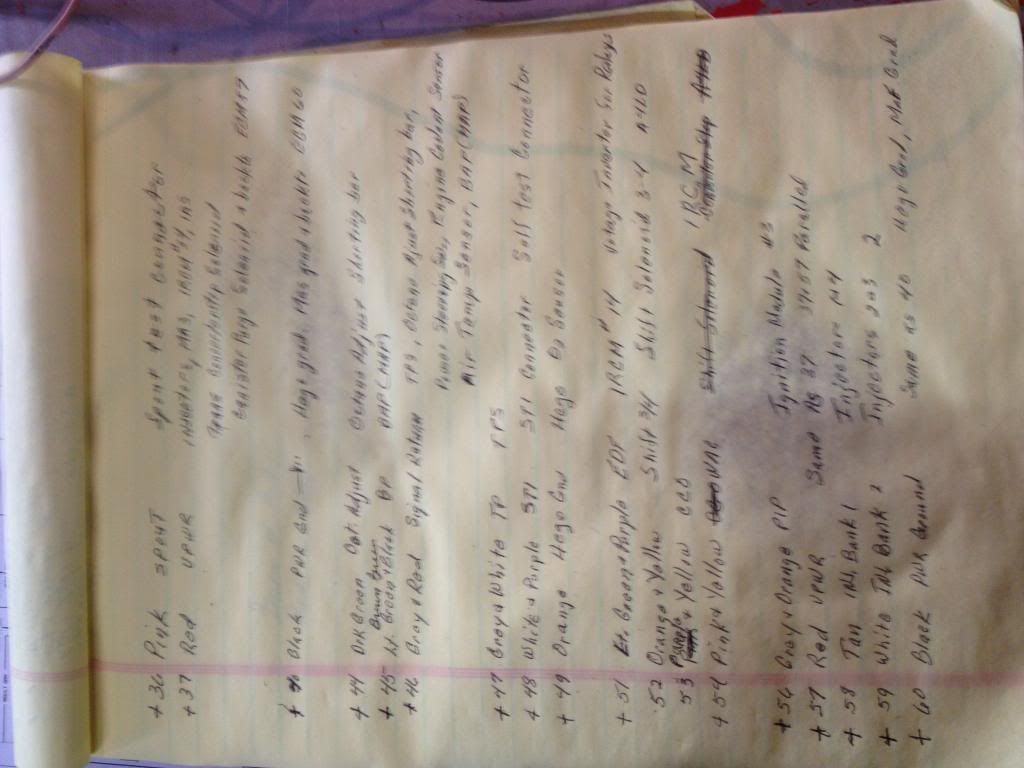

Just beginning to make two harnesses from one. we are staggering the cuts and then shrink tube and soldering the two harnesses together..

Engine control harness nearly complete.

This is the slowest part of the project with out a question. Progress is slow but sure!! We also have wired the harness for the transmission and have all of the dash instrumention leads ready so we are moving along.

Waste of time I will tell you that old undercoating is a real nasty concauction. I finally just called a comercial blaster and for 130 bucks and an hr of dinking around the frame was ready to go.

Waste of time I will tell you that old undercoating is a real nasty concauction. I finally just called a comercial blaster and for 130 bucks and an hr of dinking around the frame was ready to go.