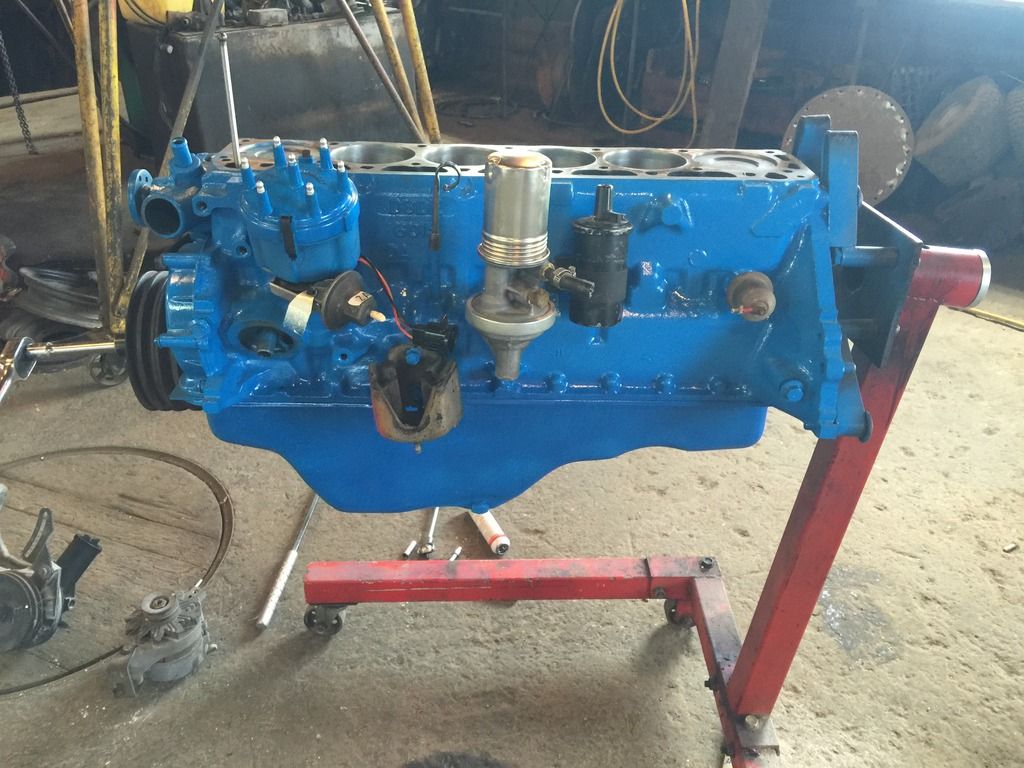

Removed the Driverside floor panel today. Worse that I thought it was. Definitely glad I elected to replace them! Back of the panel was completely shot, didn't even have to drill rivets. Weird thing is that until I scraped beliner off you would have thought it was solid.

Grinding all the loose paint off so I can por 15 to protect from corrosion like other side. Tomorrow I will put new panel in and prime. FInish prepping rest of the cab. Friday I hope to spray the white raptor liner. Entire cab interior will be raptor lined white.

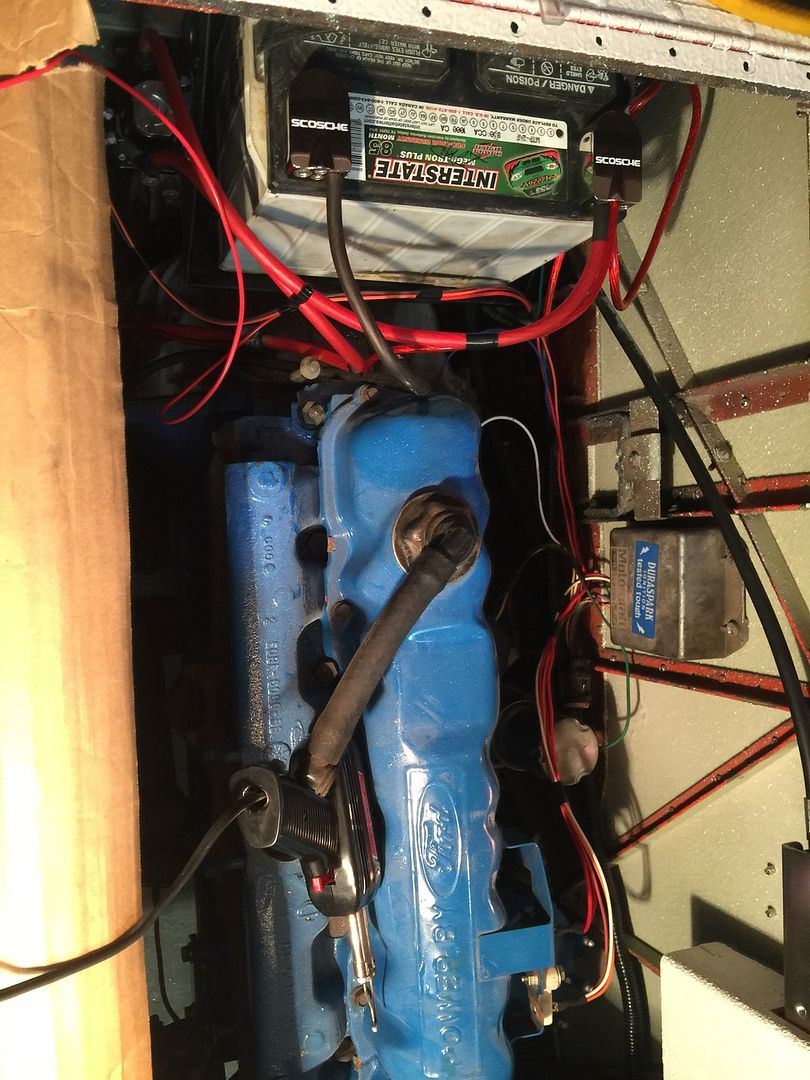

Still need to remove steering controls and throttle to prep for raptor liner. I will go through masters again to make sure there are no leaks. Don't want a mess on new floors!!

As you can see control area is a mess, wish I would have taken some before pictures. The Drivers floor pans were completely rotted and bent up.

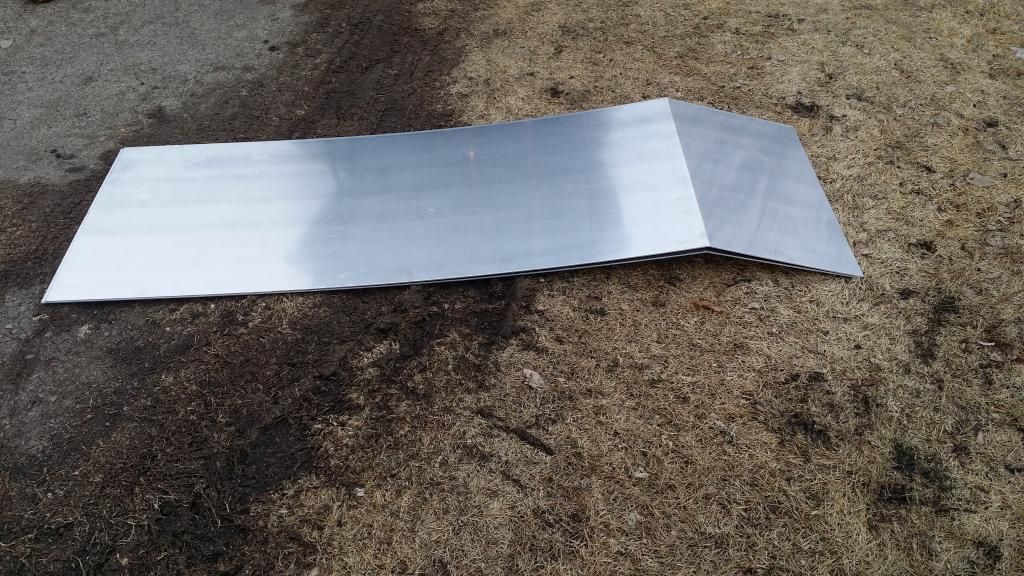

rotten footwell panel and cobbled repair plate. This one plate weighs as much as both new floor panels. Its THICK!! and of course I dropped it on my knee.

You can see what I mean about how rotten the back was in this picture. Cant wait to spray the interior on Friday and have it all clean and white!