Introduction: Snow Trac BRAKE SYSTEMS

ST 4 brakes are a world unto themselves. They are so difficult to get at when the machine is assembled that during the course of overhauling some dozen machines I made the Brake work one of the highest priorities. Without the brakes the machines can be dangerous on hills and when loading on tilt bed trailers. If you pull your engine or especially Variator out REDO the brakes system while the stuff is accessible. The entire brakes system only cost about 100 to 200 dollars to replace with entirely new components.

VW Automobiles had 4 brakes to stop a 2000 Lb. Machine. ST4's weigh upwards of 3000Lbs and only have 2 brakes to achieve the same effect. They in fact a bit under braked. At significant portion of the some hundred ST4's I've inspected had front end damage as a result of not servicing the brakes.

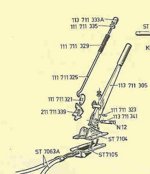

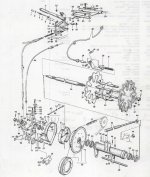

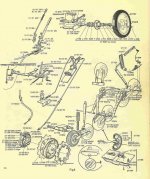

The images below are from a mid-1970's manual (I believe 1975).

ST 4 brakes are a world unto themselves. They are so difficult to get at when the machine is assembled that during the course of overhauling some dozen machines I made the Brake work one of the highest priorities. Without the brakes the machines can be dangerous on hills and when loading on tilt bed trailers. If you pull your engine or especially Variator out REDO the brakes system while the stuff is accessible. The entire brakes system only cost about 100 to 200 dollars to replace with entirely new components.

VW Automobiles had 4 brakes to stop a 2000 Lb. Machine. ST4's weigh upwards of 3000Lbs and only have 2 brakes to achieve the same effect. They in fact a bit under braked. At significant portion of the some hundred ST4's I've inspected had front end damage as a result of not servicing the brakes.

The images below are from a mid-1970's manual (I believe 1975).

and have seen several other people do it. DON"T GO THERE! BIG MISTAKE!

and have seen several other people do it. DON"T GO THERE! BIG MISTAKE!