There is one here in town,and I pass by it from time to time.

I found this article on it.

Pretty interesting (sorry for the long article).

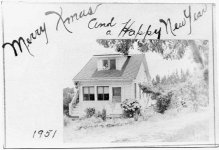

“Living in a lunchbox” or “a tin can” are a few phrases tossed at those who chose to purchase a Lustron stainless steel pre-fab home in the immediate post WWII years from 1947 to 1950.

Less than 3,000 were ever manufactured before Carl Strandlund’s idea to solve the housing shortage for veterans ended in bankruptcy.

Built in a former aircraft plant in Columbus, most of these homes ended up with home owners in the Midwest, including one in Delphos, two in Spencerville, three in Van Wert and several more in Lima.

Strandlund was a manufacturer of porcelain-coated steel panels used in that era for facades of gas stations and fast-food restaurants. He had not originally intended to build homes. Wartime restrictions on steel were still in place in 1946, so he worked with two Chicago architects to sketch out plans for all-steel, prefabricated homes to solve the housing shortage.

The Reconstruction Finance Corporation (RFC) approved his ideas, giving him a $12.5 million loan for his new business and approved an annual lease on one-half of the Curtiss-Wright plant in Columbus, which had been used during the war to build planes.

Strandlund came up with the name of Lustron (luster on steel) and the homes were advertised as “A New Standard for Living.” The homes were designed with a built-in vanity in the bedroom, storage space and sliding doors. The dining room had a built-in buffet with pass-through to the kitchen. The kitchen had an option for a built-in, under-the-sink washing machine, that with the addition of a special rack, would double as a dishwasher.

The serial number for each home was mounted in the utility room where the hot water heater and furnace was housed. The newest kind of heating was featured as a ceiling-mounted, oil-fired hot-air furnace that heated the metal ceiling tiles, which would heat the entire house.

Jim Herfurth lives in one of two adjoining Lustron properties in Spencerville.

“It didn’t work, since heat rises, the floor was cold all the time,” he said.

He has lived in his home for approximately 17 years and both he and his neighbor have rare Lustron garages on their properties.

Mike and Trina Louth, who live in one of three Lustron homes situated on State Route 118 in Van Wert, love their home.

“It’s a little more spacious because it was the 3-bedroom model but the original owner had it put together as two bedrooms, so there’s a lot more room in the living room area,” Mike Louth said.

Jennifer Schaffner, who lives in a Lustron home on East Fourth Street in Delphos, is happy just to be a first-time home owner and plans some repair and updating to her home.

“I’ve lived here four years and it’s a little small but I love it. I always wanted to be a meteorologist and I saw on a web site where a F-5 tornado struck an area where there was a Lustron home. All the wood structures around it were reduced to just splinters but the Lustron home was still standing, minus the windows and the roof,” she said.

Other advertisements claimed the homes were fire-, decay-, rust-, termite-, vermin- and rat-proof. The home would not stain, crack or peel, would never need re-painted or re-roofed and could be kept clean with a damp cloth or a hose.

The 2-3 bedroom homes took 12 tons of steel and one ton of enamel for each home, including the shingles, with an estimated cost of $6,000 to $10,000 (garages extra) and were shipped in 30,000 pieces.

Exterior color choices ranged from gray, yellow, blue-green, pink, tan and white for the 2-foot-square steel tile panels. It was estimated 400 manhours were spent in manufacturing and 300 hours assembly at the delivery site.

Houses could be ordered like a car: go to the dealership, pick a model and color and wait for delivery and assemble at the chosen site.

Strandlund’s company ran into financial trouble almost immediately. Tooling the Columbus factory was more expensive than originally estimated and the government-backed loan did not cover start up expenses.

Dealers needed $50,000-$100,000 to get started and had to buy lots, pour foundations and run utility lines. They also had to pay cash at the factory. The Federal Housing Administration slowed down the approval of mortgages for prospective buyers.

Strandlund had estimated he could produce 100 homes daily at a cost of $6,500 each. The first Lustron home was produced in March 1948. Cost of the Lustron homes grew to $11,000 compared to $8,000 for a typical 1950 wood-frame house. Only 26 homes were being made a day, with 50 needed just to break even financially.

Finally, in Feb. 1950, Lustron was foreclosed by the National Housing Agency (RCA) with a $37.5 million debt to the federal government.

Approximately 2,680 unique all-steel homes were manufactured, leaving those homeowners to struggle with repair and upkeep with their one-of-a-kind houses.

The strange washing machine-dishwasher machine was the first to go in many Lustron homes as it did not work properly. The radiant heat through the ceiling tiles was another failure with a lot of homeowners turning to baseboard heat.

There seems to be a cult revival and renewed interest in the few remaining Lustron homes in the last few years. A group with multiple chemical sensitivities were interested last year in purchasing 60 Lustron homes to be removed from the Quantico military base to make room for new housing.

Lustron homes are featured in an article in the April issue of Old-House Living magazine. Lustron homeowners have their own web site and will have their third international convention this year in June in Cedar Rapids.

Perhaps those collectors of 1940s and ‘50s memorabilia are looking for more than an old Volkswagon or “I Love Lucy” items. If one just has an estimated $65,000-$125,000 to dissemble and move a Lustron onto a lot, then all one will need is the 207-page original book to help put it all together again.

I found this article on it.

Pretty interesting (sorry for the long article).

“Living in a lunchbox” or “a tin can” are a few phrases tossed at those who chose to purchase a Lustron stainless steel pre-fab home in the immediate post WWII years from 1947 to 1950.

Less than 3,000 were ever manufactured before Carl Strandlund’s idea to solve the housing shortage for veterans ended in bankruptcy.

Built in a former aircraft plant in Columbus, most of these homes ended up with home owners in the Midwest, including one in Delphos, two in Spencerville, three in Van Wert and several more in Lima.

Strandlund was a manufacturer of porcelain-coated steel panels used in that era for facades of gas stations and fast-food restaurants. He had not originally intended to build homes. Wartime restrictions on steel were still in place in 1946, so he worked with two Chicago architects to sketch out plans for all-steel, prefabricated homes to solve the housing shortage.

The Reconstruction Finance Corporation (RFC) approved his ideas, giving him a $12.5 million loan for his new business and approved an annual lease on one-half of the Curtiss-Wright plant in Columbus, which had been used during the war to build planes.

Strandlund came up with the name of Lustron (luster on steel) and the homes were advertised as “A New Standard for Living.” The homes were designed with a built-in vanity in the bedroom, storage space and sliding doors. The dining room had a built-in buffet with pass-through to the kitchen. The kitchen had an option for a built-in, under-the-sink washing machine, that with the addition of a special rack, would double as a dishwasher.

The serial number for each home was mounted in the utility room where the hot water heater and furnace was housed. The newest kind of heating was featured as a ceiling-mounted, oil-fired hot-air furnace that heated the metal ceiling tiles, which would heat the entire house.

Jim Herfurth lives in one of two adjoining Lustron properties in Spencerville.

“It didn’t work, since heat rises, the floor was cold all the time,” he said.

He has lived in his home for approximately 17 years and both he and his neighbor have rare Lustron garages on their properties.

Mike and Trina Louth, who live in one of three Lustron homes situated on State Route 118 in Van Wert, love their home.

“It’s a little more spacious because it was the 3-bedroom model but the original owner had it put together as two bedrooms, so there’s a lot more room in the living room area,” Mike Louth said.

Jennifer Schaffner, who lives in a Lustron home on East Fourth Street in Delphos, is happy just to be a first-time home owner and plans some repair and updating to her home.

“I’ve lived here four years and it’s a little small but I love it. I always wanted to be a meteorologist and I saw on a web site where a F-5 tornado struck an area where there was a Lustron home. All the wood structures around it were reduced to just splinters but the Lustron home was still standing, minus the windows and the roof,” she said.

Other advertisements claimed the homes were fire-, decay-, rust-, termite-, vermin- and rat-proof. The home would not stain, crack or peel, would never need re-painted or re-roofed and could be kept clean with a damp cloth or a hose.

The 2-3 bedroom homes took 12 tons of steel and one ton of enamel for each home, including the shingles, with an estimated cost of $6,000 to $10,000 (garages extra) and were shipped in 30,000 pieces.

Exterior color choices ranged from gray, yellow, blue-green, pink, tan and white for the 2-foot-square steel tile panels. It was estimated 400 manhours were spent in manufacturing and 300 hours assembly at the delivery site.

Houses could be ordered like a car: go to the dealership, pick a model and color and wait for delivery and assemble at the chosen site.

Strandlund’s company ran into financial trouble almost immediately. Tooling the Columbus factory was more expensive than originally estimated and the government-backed loan did not cover start up expenses.

Dealers needed $50,000-$100,000 to get started and had to buy lots, pour foundations and run utility lines. They also had to pay cash at the factory. The Federal Housing Administration slowed down the approval of mortgages for prospective buyers.

Strandlund had estimated he could produce 100 homes daily at a cost of $6,500 each. The first Lustron home was produced in March 1948. Cost of the Lustron homes grew to $11,000 compared to $8,000 for a typical 1950 wood-frame house. Only 26 homes were being made a day, with 50 needed just to break even financially.

Finally, in Feb. 1950, Lustron was foreclosed by the National Housing Agency (RCA) with a $37.5 million debt to the federal government.

Approximately 2,680 unique all-steel homes were manufactured, leaving those homeowners to struggle with repair and upkeep with their one-of-a-kind houses.

The strange washing machine-dishwasher machine was the first to go in many Lustron homes as it did not work properly. The radiant heat through the ceiling tiles was another failure with a lot of homeowners turning to baseboard heat.

There seems to be a cult revival and renewed interest in the few remaining Lustron homes in the last few years. A group with multiple chemical sensitivities were interested last year in purchasing 60 Lustron homes to be removed from the Quantico military base to make room for new housing.

Lustron homes are featured in an article in the April issue of Old-House Living magazine. Lustron homeowners have their own web site and will have their third international convention this year in June in Cedar Rapids.

Perhaps those collectors of 1940s and ‘50s memorabilia are looking for more than an old Volkswagon or “I Love Lucy” items. If one just has an estimated $65,000-$125,000 to dissemble and move a Lustron onto a lot, then all one will need is the 207-page original book to help put it all together again.