-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

snow trac vw carb heat tube leaks

- Thread starter JimVT

- Start date

nikos

Active member

it's kind of a leak. i'm not sure what i'll do.

timberline is getting closer .i'll need to do something.

JimVT you don't have to worry about that kind of leak. It came from the seals of the generator stand and for some reason from the oil filler.

I am not a mechanical, but i just walked this dirty path with the oil leaks, two weeks ago. ( I will post soon all the photos from this project in my thread.)

After the Timberline Party, you have plenty of time to fix the oil leaks ok

Nikos

thanks nikos

did you see the hole? it is right above the tin on the heat tube. diamond shape about the size of a medium small pearl. when started on choke at running higher rpm's it blows a good amount of exhaust out.

this is a stale air engine. will it get to the cab?

very strong good running 1200cc .

jim

did you see the hole? it is right above the tin on the heat tube. diamond shape about the size of a medium small pearl. when started on choke at running higher rpm's it blows a good amount of exhaust out.

this is a stale air engine. will it get to the cab?

very strong good running 1200cc .

jim

Last edited:

nikos

Active member

thanks nikos

did you see the hole? it is right above the tin on the heat tube. diamond shape about the size of a medium small pearl. when started on choke at running higher rpm's it blows a good amount of exhaust out.

this is a stale air engine. will it get to the cab?

very strong good running 1200cc .

jim

I saw the holes both of them. Where is the tinware and the air hose.

Did you have them? Did you use the ST4 without them?

Some times when (the tinware and the air hose) they have not been, well fitted in the hole, it happens to blow a good amount of exhaust out.

I know because it happens to me.

Now i have already fix this problem with the tinware and the fumes, and fresh air goes straight to the heat exchanger.

I think the problem with the fumes into the cab........

Jim I will check my notes and after that i ll answer to your question ok.

Nikos

The first foto is from last year, when i realised the problem with the oil leak, and I had to replace the broken generator with a new alternator.

The second foto is today

Nikos

Attachments

Some furnace cement and a small piece of heavy duty metal tape around the whole mess.. Just a farmer fix!

Regards, Kirk

Regards, Kirk

Some furnace cement and a small piece of heavy duty metal tape around the whole mess.. Just a farmer fix!

Regards, Kirk

Maybe a piece of muffler repair tape?

Jim

Sno-Surfer

Active member

I think Nikos might be confused with looking at the holes in the tin for the heater tubes.

JimVT is talking about the pre heater that heats the carb up, it's all one piece on the intake manifold. I think for the Timberline event I would just JB weld it but it looks like your due to get another one with more life left in it. Not hard to find and you can order an after market one. You could also slip block off gaskets where it hooks to the exhaust and just not have a working pre heater. It will still run fine.

JimVT is talking about the pre heater that heats the carb up, it's all one piece on the intake manifold. I think for the Timberline event I would just JB weld it but it looks like your due to get another one with more life left in it. Not hard to find and you can order an after market one. You could also slip block off gaskets where it hooks to the exhaust and just not have a working pre heater. It will still run fine.

nikos

Active member

I think Nikos might be confused with looking at the holes in the tin for the heater tubes.

JimVT is talking about the pre heater that heats the carb up, it's all one piece on the intake manifold. I think for the Timberline event I would just JB weld it but it looks like your due to get another one with more life left in it. Not hard to find and you can order an after market one. You could also slip block off gaskets where it hooks to the exhaust and just not have a working pre heater. It will still run fine.

Thank you Snow Surfer

I didn't see at the beginning of the conversation, the small hole with the diamond shape on the intake manifold, and i was trying to understand, to focus in the way, how the fumes are coming back from the biggest hole of the heater exchanger.

Then i realized that it was a different type of vw motor.

Anyway i hope to Jim VT to fix this kind of problem with or without the sheet tape ( that we used sometimes) and of course we expect from Jim many fotos from the Timberline event.

Nikos

nikos

Active member

I may be pulling the engine soon.

As Don saying, Its about 8 hours and its only four screws.

I spent two months (From December till the end of February - to busy ) and i had to unscrew dozens of screws, because The Doctors - The good guys in the garage, decide for some reason to pull the engine from the front side.

Nikos

Jim it will require replacement of the intake sorry to say one could make block off gaskets for it but it would impair performance in cold and damp conditions

nikos

Active member

In this way from the front side you need time, to many patience, no nerves and of cource and NO SNOW. (This Winter, it was one of the warmest Winter i ever seen, I don't remember anything like that the previous decades ).

But it's a good opportunity to replace all the old and worn screws, with the new ones.

Nikos

But it's a good opportunity to replace all the old and worn screws, with the new ones.

Nikos

Attachments

Jim it will require replacement of the intake sorry to say one could make block off gaskets for it but it would impair performance in cold and damp conditions

I have a good used 1600 that was in a bus that needs a carb on my shop floor.

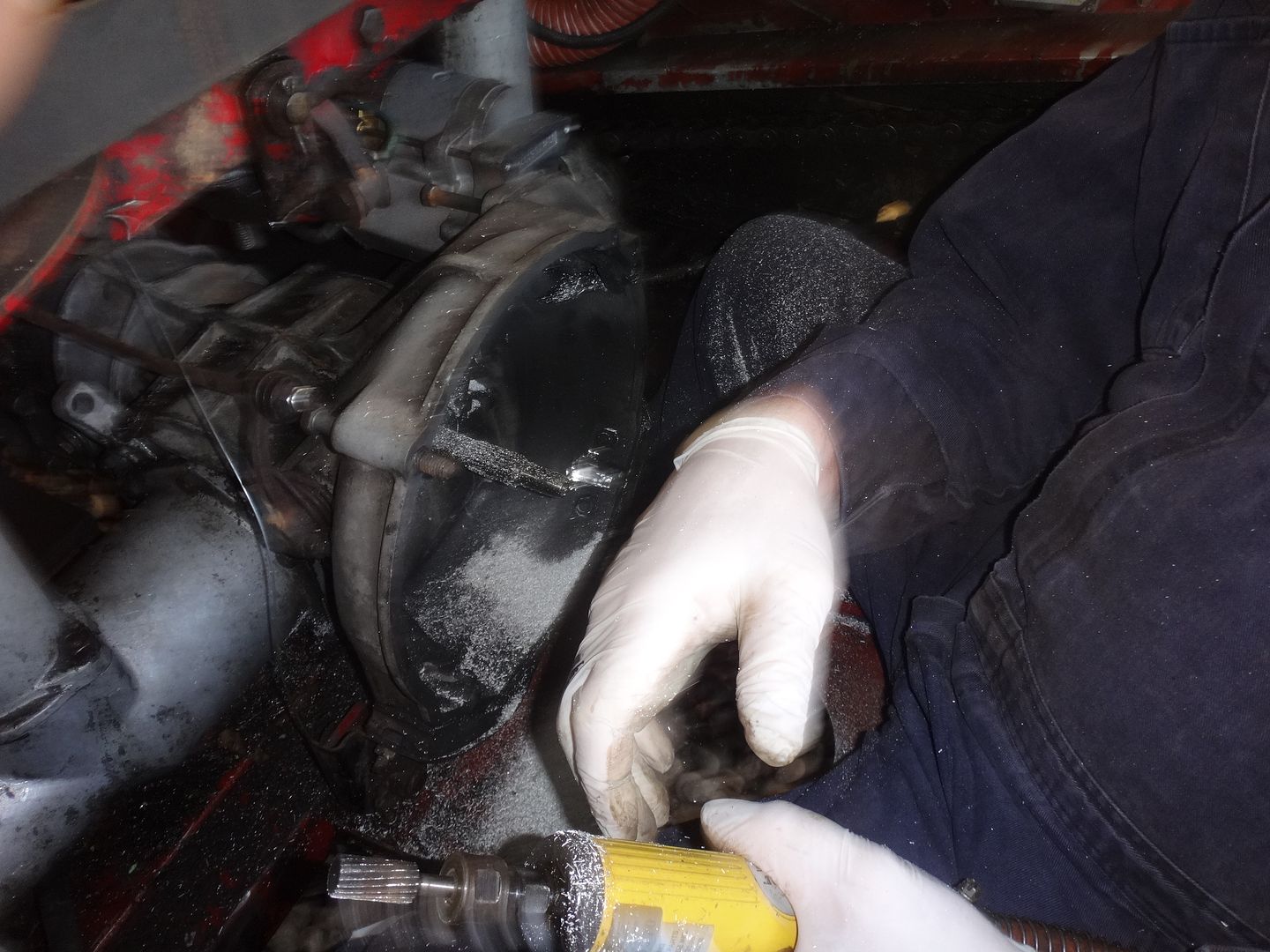

i'm not sure what is needed for the conversion but I fitted it to a rebuilt spare st4 tranny so the heat tubes cut and clutch housing have been ground. this is a photo of the air horn being built.

it has a bus exhaust .can that be used? I may need to replace it . the tailpipe got busted off in the accident that it came from.

jim

maybe turbonator has a oxygen mask I could borrow.

You mean like this one? The infamous MBU-5. One of the most uncomfortable devices designed by man. They could use these to torture terrorists, but that would be inhumane.

Short term fix- use a piece of high temp gasket material and a hose clamp.

Long term fix- clean up the surface and silver solder a new piece of sheet metal over the hole.

Either way, still better than sucking O's.

Attachments

Sno-Surfer

Active member

Jimvt, the bus exhaust will work, at least that is what I have on mine. If that is an original muffler in real good shape, it might be worth tacking that tail piece back on. Otherwise I would order a new muffler while it's out. The new mufflers don't fit entirely right at the heater boxes but you can fix that with a little bit of the heater hose. There is usually a wide clamp that connects the heater tube to the heater boxes but it's not quite wide enough and therefore leaves a gap and you will loose some heat to the cabin. Not a big deal and easy fix but just FYI.

If you want "the man" to rebuild the carb for you call or send a note to Tim at Volksbitz. He is in Yelm and you will not be disappointed with his work or prices it will come back better than new.

Volksbitz.com 360-894-8787

Also I would replace the distributor on that 1600. It looks like you have a .009 on it now and I would replace it with either a 205q DVDA model or something equivalent. It will run a lot better and start out in gear much easier. I have an extra one you could try out at the Timberline event this year if you want.

If you want "the man" to rebuild the carb for you call or send a note to Tim at Volksbitz. He is in Yelm and you will not be disappointed with his work or prices it will come back better than new.

Volksbitz.com 360-894-8787

Also I would replace the distributor on that 1600. It looks like you have a .009 on it now and I would replace it with either a 205q DVDA model or something equivalent. It will run a lot better and start out in gear much easier. I have an extra one you could try out at the Timberline event this year if you want.

Sno-Surfer

Active member

Just noticed your 1600 is a single port. You could also use a svda distributor like a 205t.

I had to recruit some help. lyndon is stopping in to help with the install. I've done one he has done 6. kind of a drop in party .

when you put a 1600 in the first time it brushes the tranny housing a few spots. you pull the engine and grind the spots down. it takes a few times.

good thing I had the replacement checked out. the clutch plates were stuck .

for those who have trouble reading i'll get a photo.

jim

when you put a 1600 in the first time it brushes the tranny housing a few spots. you pull the engine and grind the spots down. it takes a few times.

good thing I had the replacement checked out. the clutch plates were stuck .

for those who have trouble reading i'll get a photo.

jim

Hey Jim, I did the 16 flywheel fitment you explained, I recommend Painting the steel items in the bell housing blaze orange.

I put it in the housing and turned the crank to mill off the material.

then used a grinder to clearance the rest of the way.

I bumped a metal fastener of some sort it, and it was a fourth of july celebration complete with sparklers. In my infinite wisdom I pushed my thumb down on some burning metal to extinguish and the scar is still visible.

Not trying to create panic just read with interest the post about magnisium in the case

I put it in the housing and turned the crank to mill off the material.

then used a grinder to clearance the rest of the way.

I bumped a metal fastener of some sort it, and it was a fourth of july celebration complete with sparklers. In my infinite wisdom I pushed my thumb down on some burning metal to extinguish and the scar is still visible.

Not trying to create panic just read with interest the post about magnisium in the case

mike you should use sanding discs to do your final cutting on the mag case not a grinding wheel your mistake isn't the first you can have a serious quick flash in front of your face purple k is the only thing that will put out metal fires

Sno-Surfer

Active member

Cool! Looks like you had about the best help you can get!

SnowTrac Hunter

New member

Glad to see Lyndon working on a project again. Always interesting to work with. Hope it all goes well.