Well....lets not take it that far .

The little tag along is way cool....but I really don't have a use for a pup trailer.

I THINK (Subjective) that the basics are pretty well coming together now, and as far as any major CHANGE ORDERS go I hope things can continue to move along on the current direction and not need any major changes

The Cab from the S10 and the pickup box are pretty well chiseled in stone now.

This plan makes repairs and access easy......

The hydraulic steering and losing the air system just makes good sense....

As long as we stay with the small block Chevy and the TH350 tranny anything can pretty much work.

The one thing that is still sitting in the wings though is the idea of replacing the little 305 with a small block 400.

The 305 will be fine and get things up and running so the package can be wrung out and bugs worked through.

Do I need a 400....NO but it's an I want.

I had originally gave thought to using a 6.2 Diesel....Just too big...too heavy....

The 6.2 fully dressed is about 700lbs and the small block is about 450lb (The 391 Ford weighed 650)

The weight reduction will save the front axle some extra beating..

I would like to fit whatever SBC that ends up in the package with a large capacity gated oil pan that can handle steep up and down grades without oil starvation.

The 391 Ford that was in the 2100 had a deep sump pan to maintain good oil reserves to the pump

I am removing the big sump in the tub that the pan fit in...Gonna clean up the belly of the beast.

Come summer the power pack will come back out to finish welding the mounts and then clean up the bottom of the tub.

That includes fitting a cover plate over a big hole in the belly under the tranny that was cut by others at some time.

At least the plate came with the cat....

Back in my boat racing day we used a wide pan with gates that allowed oil to flow back to the pump but not the other way.

The gates also prevented tight turns at speed from tossing oil away from the pump.

For now the stock chevy pan will gitterdone.

The venerable mouse motor is so cheap and so easy to get anything to fit.

There is probably an adapter kit to bolt a mouse motor to a mail box....

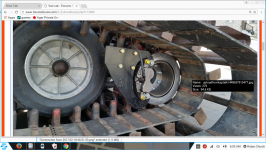

New caliper brackets10.jpg203.6 KB · Views: 65

New caliper brackets10.jpg203.6 KB · Views: 65 New caliper brackets12.jpg333.1 KB · Views: 62

New caliper brackets12.jpg333.1 KB · Views: 62 New caliper brackets13.jpg285.4 KB · Views: 63

New caliper brackets13.jpg285.4 KB · Views: 63 Nrew caliper brackets14.jpg317.4 KB · Views: 73

Nrew caliper brackets14.jpg317.4 KB · Views: 73 New caliper brackets15.jpg311.8 KB · Views: 65

New caliper brackets15.jpg311.8 KB · Views: 65 Screenshot from 2018-02-03 06:03:10.png985.3 KB · Views: 66

Screenshot from 2018-02-03 06:03:10.png985.3 KB · Views: 66

like you said, save a lot of wear on the bands if it works.

like you said, save a lot of wear on the bands if it works.

I'm sure the brakes will be adequate. Unless you have the parts already, should take a look at a hydroboost system from a typical 80s chevy diesel pick up might be a bit easier to package without the big vacuum booster. Looking forward to seeing what you come up with!

I'm sure the brakes will be adequate. Unless you have the parts already, should take a look at a hydroboost system from a typical 80s chevy diesel pick up might be a bit easier to package without the big vacuum booster. Looking forward to seeing what you come up with!