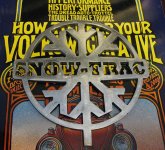

I originally intended to cut a hood ornament from 1/4" steel, but I think it's a bit on the large size. Any smaller and I was losing detail in the lettering because of the plasma "kerf." What do you think? I think to really get the level of detail, a hood ornament needs to be cast. I'll have to resurrect my foundry one of these days, make a decent mold, and cast one out of aluminum or brass.

-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

snow trac hood ornament?

- Thread starter mtmogs

- Start date

very nice.

if you really want to go smaller or lighter, you might consider etching a piece of brass with ferrous oxide.

you can cover the medallion with wax or spray paint as a resist, use a stylus to scrape away the resist in whatever pattern you want, then put the piece of metal upside down in a ferrous oxide bath. Ferrous oxide can be found at radio shack.

if you really want to go smaller or lighter, you might consider etching a piece of brass with ferrous oxide.

you can cover the medallion with wax or spray paint as a resist, use a stylus to scrape away the resist in whatever pattern you want, then put the piece of metal upside down in a ferrous oxide bath. Ferrous oxide can be found at radio shack.

Bob, The outer circle is about 5.25" in diameter. Yes, it's a little big to be a hood ornament. I could hang it off a chain and wear it around my neck "gangsta" style. It would make a nice car badge, or maybe I will use it as to cap my front winch adapter. My wife wants to use it as a trivet! I can make these in any size, pretty simple using my cnc machine, but this is probably about the smallest while getting good detail on the lettering. I thought about cutting some headlight covers using this pattern or a fold-down step for below the rear door. Any other ideas?

Not sure I'd use it as a hood ornament, but that is awesome. What is the diameter?

It seems like it could be a good car badge to mount on the back hatch of an SUV, etc.

That sounds like an interesting process Erik, thanks. Can you etch all the way through a piece of brass to create a silhouette, or do you just produce a thin bit of surface relief?

very nice.

if you really want to go smaller or lighter, you might consider etching a piece of brass with ferrous oxide.

you can cover the medallion with wax or spray paint as a resist, use a stylus to scrape away the resist in whatever pattern you want, then put the piece of metal upside down in a ferrous oxide bath. Ferrous oxide can be found at radio shack.

Bob, if you want smaller, try cutting the badge (can't spell silhouette) out with a jewellers piecing saw for metal ie copper or brass - if in copper it could be enamelled with any colour you want. Alternatively for a bit larger, cut it out in wood with a coping saw or an electric jig saw! Will have a think about the copper version, but I will have to get my piercing saw back as I lent it to our local blacksmith months ago and it still hasn't returned.

yes, with thin metal the ferrous oxide will etch all the way through. If you want to etch steel, nitric acid works well, as does sufuric and muriatic. While HNO3 is faster and less smelly, the other 2 are much easier to come by. The thicker a metal you use, the less crisp the edges will be.

you could also try lost wax casting - carve your emblen out of wax, then cast it in plaster. Once the plaster is well dried, not just cured, you can melt or burn the wax out of it, then pour melted brass, pewter, or even solder into the cavity.

you could also try lost wax casting - carve your emblen out of wax, then cast it in plaster. Once the plaster is well dried, not just cured, you can melt or burn the wax out of it, then pour melted brass, pewter, or even solder into the cavity.

utahwilson

New member

Great idea! except you misspelled TRACK-MASTER

Thanks for all of your good suggestions! I think your comments inspired Ice Queen to come up with a nice badge.

KG, by CNC machine, I meant to say that it's a CNC plasma cutting system. I do have a little lathe/mill/drill that can be retrofitted to CNC, I can even use the same motors/controllers/software, but I think it would be too sloppy for this kind of work. I'd have to fit some quality lead screws etc...$$$. Do you have a CNC mill setup?

Snowbird, using epoxy to make easily machinable molds is a good idea. I used to use auto body filler to do the same for green-sand castings in my little foundry. It hardens quickly, is easily workable and sands to a very smooth finish.

Erik, ah yes..the lost wax method. Used it in HS art class to make jewelery. This is probably the easiest technique for making smaller things.

This project was just the tail-wagging-the-dog though, just messing around with the plasma cutter. I originally built it make machinery parts etc. Here is a vid of the first project I completed with it, a snowblower for my skidsteer

plasma cut snowblower

KG, by CNC machine, I meant to say that it's a CNC plasma cutting system. I do have a little lathe/mill/drill that can be retrofitted to CNC, I can even use the same motors/controllers/software, but I think it would be too sloppy for this kind of work. I'd have to fit some quality lead screws etc...$$$. Do you have a CNC mill setup?

Snowbird, using epoxy to make easily machinable molds is a good idea. I used to use auto body filler to do the same for green-sand castings in my little foundry. It hardens quickly, is easily workable and sands to a very smooth finish.

Erik, ah yes..the lost wax method. Used it in HS art class to make jewelery. This is probably the easiest technique for making smaller things.

This project was just the tail-wagging-the-dog though, just messing around with the plasma cutter. I originally built it make machinery parts etc. Here is a vid of the first project I completed with it, a snowblower for my skidsteer

plasma cut snowblower