-

Please be sure to read the rules and adhere to them. Some banned members have complained that they are not spammers. But they spammed us. Some even tried to redirect our members to other forums. Duh. Be smart. Read the rules and adhere to them and we will all get along just fine. Cheers. :beer: Link to the rules: https://www.forumsforums.com/threads/forum-rules-info.2974/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

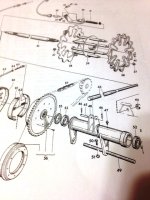

Help! Need Snow Trac Sprocket

- Thread starter akimp

- Start date

Hi Akimp, I am sorry, I don't know much about the Snow Trac. But........have you thought about buying a sprocket that fits the chain, and then taking the old sprocket and the new sprocket to a machine shop ( or anyone with a lathe) turn the splined portion of the old sprocket out and machine the inside of the new sprocket to accept the spine portion and weld that into the new sprocket.......If I understand what you are saying...then this should work....sorry if I still don't understand it....I am just trying to help with a few ideas.....

Good luck

Bruce

Good luck

Bruce

for him it's the splined section that has wore out it's real common on snow tracs for both the hubs and sprockets to do that especially if the machine has been run with the nuts loose in the past. if you catch it soon enough you can fill the voids with jb weld it will than last a life time.

Oh.....thanks for filling me in. I guess I am just too cheap and in to much of a hurry to want to wait and find the "right" part....I would rather try to make one and not be dependent on others.....what about finding another splined item ( such as a pto shaft spline..or whatever else shares that spline pattern, and weld it in as suggested. I have also cut splines on my lathe...any decent machine shop and cut splines...Also, I have made patterns, so if JB weld is so good ( I have never had much luck with it....) could you make a spline pattern and "cast" the spines in JB weld? ( I really don't think that is a very good idea though...) Are there any spines left on the shaft? or are they just gone from the sprocket? sounds like just gone from the sprocket. A series of key stock set into the spines on the axle could be welded to a ring and then welded into the sprocket to make a spine hub......again, just ideas.........( OK...I will sit on my hands now and watch what you decide to do....) ....again, good luck.

I've pulled 8000 pounds on my jb weld fix I know it works well once the splines are gone jb weld wont work. you can only use it on worn splines that are loose. the hub on the worn sprocket I have is good and that is why I keep it around ,some day I will have to lathe it out and weld on a new sprocket. I have seen where others have slotted hubs and axles for keyed shafts, and one member also had a machine shop make new ones for him. out in the bush we don't have the convenience of a machine shop. in my town we are lucky I have a lathe and end mill, or stuff gets shipped to anchorage. the tooth pitch is an iso pattern not sae #80 like it looks like .Oh.....thanks for filling me in. I guess I am just too cheap and in to much of a hurry to want to wait and find the "right" part....I would rather try to make one and not be dependent on others.....what about finding another splined item ( such as a pto shaft spline..or whatever else shares that spline pattern, and weld it in as suggested. I have also cut splines on my lathe...any decent machine shop and cut splines...Also, I have made patterns, so if JB weld is so good ( I have never had much luck with it....) could you make a spline pattern and "cast" the spines in JB weld? ( I really don't think that is a very good idea though...) Are there any spines left on the shaft? or are they just gone from the sprocket? sounds like just gone from the sprocket. A series of key stock set into the spines on the axle could be welded to a ring and then welded into the sprocket to make a spine hub......again, just ideas.........( OK...I will sit on my hands now and watch what you decide to do....) ....again, good luck.