Sigh.....

In connection with my previous thread regarding needing a larger tractor because of it's inability to efficiently plow the drive, I was plowing the drive again this evening after some snow and wind today had deposited about 18" of drifts on almost the entire length of the drive, when just as I was finishing (LUCKY!), I noticed that as I was backing up to push another pile with the FEL, the tractor wouldn't turn. Thinking that I was just on a slick spot, I tried to turn again (made sure the 4WD hadn't disengaged). Looking down at the wheels, I could see the hydraulic cylinder extending and retracting. What the?! So I stop and dismount, grab a flashlight and look under the front axle.

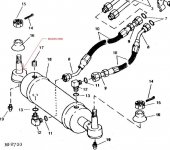

The fixed mounting point of the steering cylinder broke free!!!

Need to get the new assembly on order ASAP before more snow heads in.

In connection with my previous thread regarding needing a larger tractor because of it's inability to efficiently plow the drive, I was plowing the drive again this evening after some snow and wind today had deposited about 18" of drifts on almost the entire length of the drive, when just as I was finishing (LUCKY!), I noticed that as I was backing up to push another pile with the FEL, the tractor wouldn't turn. Thinking that I was just on a slick spot, I tried to turn again (made sure the 4WD hadn't disengaged). Looking down at the wheels, I could see the hydraulic cylinder extending and retracting. What the?! So I stop and dismount, grab a flashlight and look under the front axle.

The fixed mounting point of the steering cylinder broke free!!!

Need to get the new assembly on order ASAP before more snow heads in.