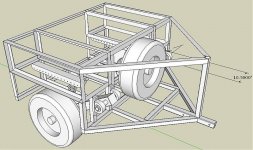

You guys got me think about the suspension on my IMP again. I have not had the chance to work on it lately, but have put some thought into the design I came up with. I attached a few more pictures to better illustrate what I am trying to to do. I value the engineering savvy of you guys and appreciate any comments or suggestions.

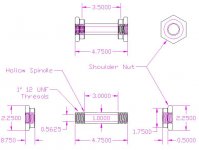

I an effort to get the maximum results per $ I am trying to use these surplus axles I came across a few months back. this guy is literally selling these 1400# axle assemblies to me for $50 a piece, and he has allot of them. Enough to share with my IMP'ing friends if this works out

Before final welding I intend on using a fixture to make sure all the hubs are in line with the rear end and square to the rest of the machine.

So the prototype mounting plates I had made at my shop are just that prototypes and can be changes in anyway to accommodate attack angles, ride heights, camber, ect.

I guess I have a few concerns I would like to ask the experts opinions on, and please feel free to toss any possible suggestions out there.

The fist is track and guide clearance; I have 24" drop center grousers, will they clear, if not will small well placed "skid" plates solve the problem?

The second is proper suspension for weight; Will the 700# each torsion units be enough, or can they be rotated to individually tune the specific location they have on the machine?

The third is original frame strength; is the new setup going to exert more twisting force one the frame member it is mounting to than the stock units did? if so is it too much for the design of the IMP frame?

The forth is mounting plate thickness; Is 1/4" material strong enough or should I go to 3/8"?

Would you disclose the maker of the torsion axles? I like that they are adjustable.

Would you disclose the maker of the torsion axles? I like that they are adjustable.

Before final welding I intend on using a fixture to make sure all the hubs are in line with the rear end and square to the rest of the machine.

Before final welding I intend on using a fixture to make sure all the hubs are in line with the rear end and square to the rest of the machine.